Aarons Drag CQ: 3-29 anodized and welded stuff. AN lines

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

:woowoo: :woowoo: getting exciting

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

:stupid: :stupid: :stupid: :stupid: :stupid: :stupid: :stupid: :stupid: :slap:

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

speeding-g60 wrote:i saw something yesterday, at a welders house, a catch can

:-D

its quite the beast

esp compared to the old one

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

ok. mounted harness front and side belts. cant do shoulder belts til the seat back brace is welded to harness bar of cage.

drilled and Cleco'd the sunroof panel. will get silicone in the morning and rivet it in place.

put seat back in to make the seat back bracing in the morning.

will get fluids to fill diff and trans.

then its all motor-related from there on out.

drilled and Cleco'd the sunroof panel. will get silicone in the morning and rivet it in place.

put seat back in to make the seat back bracing in the morning.

will get fluids to fill diff and trans.

then its all motor-related from there on out.

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

seat brace done.

harness done.

sunroof riveted and sealed.

new shelves built in garage. done. organization is key. i like to try anyhow.

now all that is left is pretty much dependent on the motor being in place.

terminating the gauge sensors.

wiring the starter and alternator.

cooling hoses and oiling hoses.

slap all the fuel lines on.

mmmmmmm. cant wait..... getting reeeeeeeaaaalll close now.....

once running and driving, i will load it up and take it for alignment. then directly after that, off to the truck scale, get a rough idea. hell, i will just go there before hand and weigh the empty trailer. then weigh it again with the car on. will get a rough idea anyhow. but i will be fully pleased to see something like 22xx wet weight no driver. and ecstatic if it were in the 21xx range. holy shit could i be so lucky.

harness done.

sunroof riveted and sealed.

new shelves built in garage. done. organization is key. i like to try anyhow.

now all that is left is pretty much dependent on the motor being in place.

terminating the gauge sensors.

wiring the starter and alternator.

cooling hoses and oiling hoses.

slap all the fuel lines on.

mmmmmmm. cant wait..... getting reeeeeeeaaaalll close now.....

once running and driving, i will load it up and take it for alignment. then directly after that, off to the truck scale, get a rough idea. hell, i will just go there before hand and weigh the empty trailer. then weigh it again with the car on. will get a rough idea anyhow. but i will be fully pleased to see something like 22xx wet weight no driver. and ecstatic if it were in the 21xx range. holy shit could i be so lucky.

:-D :-D :woowoo: :woowoo:

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

-

fasterthenrs2

(can envision aaron checking tracking number every 20 mins)

i do the same thing

i do the same thing

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

no, not the motor in shipping. we refreshed the rabbit motor to start the car up for its first track day. no need to make things super complicated and worry about untried tune, etc. this way i can focus on car only, not motor as well.

this motor is at the shop that built the big head.... i should be able to pick it up this week. it is a side-project for them, so it does not take spotlight attention. they have a business to run, and help with my stuff when time allows.

this motor is at the shop that built the big head.... i should be able to pick it up this week. it is a side-project for them, so it does not take spotlight attention. they have a business to run, and help with my stuff when time allows.

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

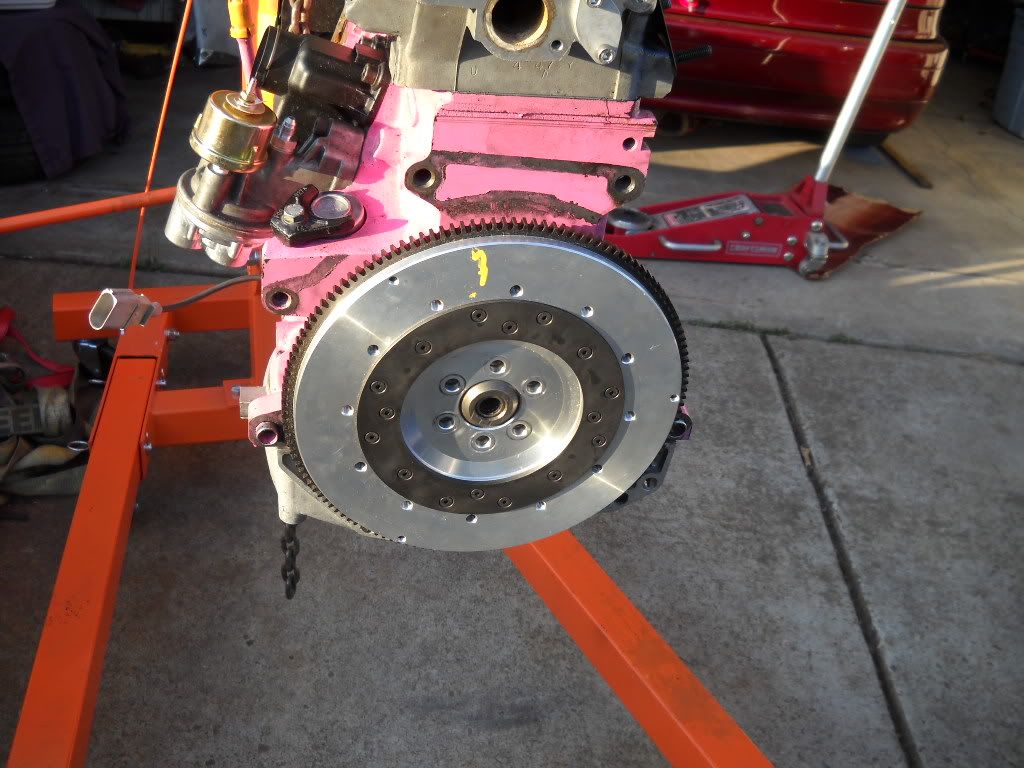

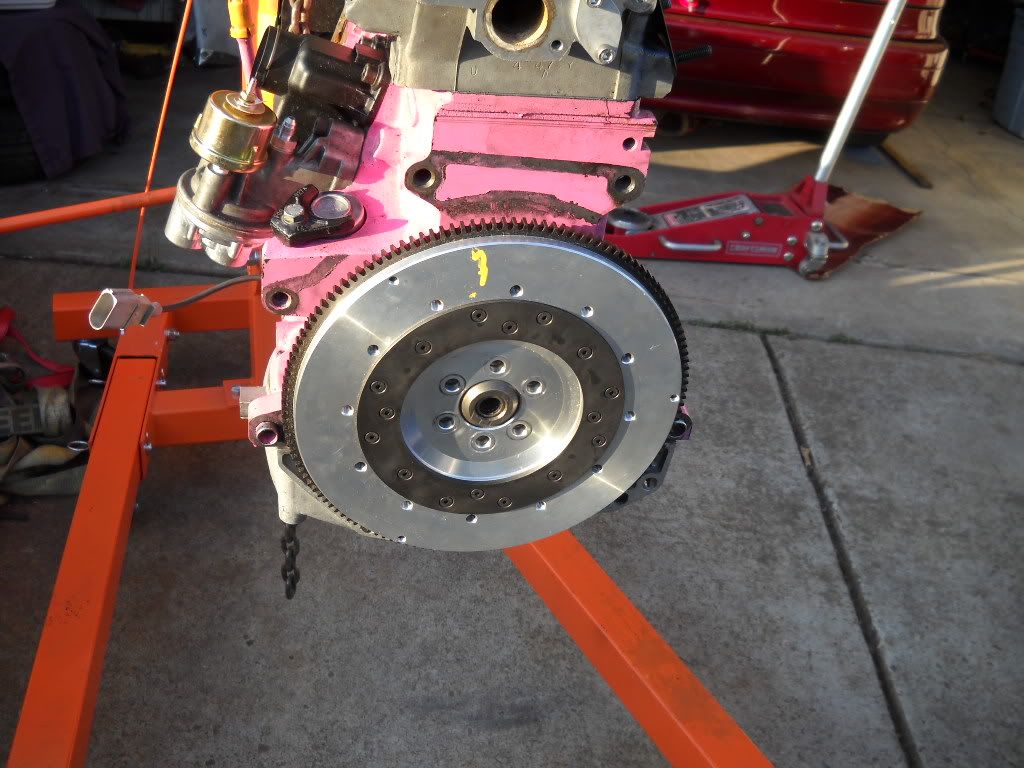

sooooo. got the pink motor back today.

spent a few hours doin stuff finally WOOWOO!!!!

and its no wife-child weekend, so this will be running veeeerrrrrryyyy soon.

starting point.

flywheel. mmmm, aluminum twin disc clutch setup. SF! rated. mmmm.

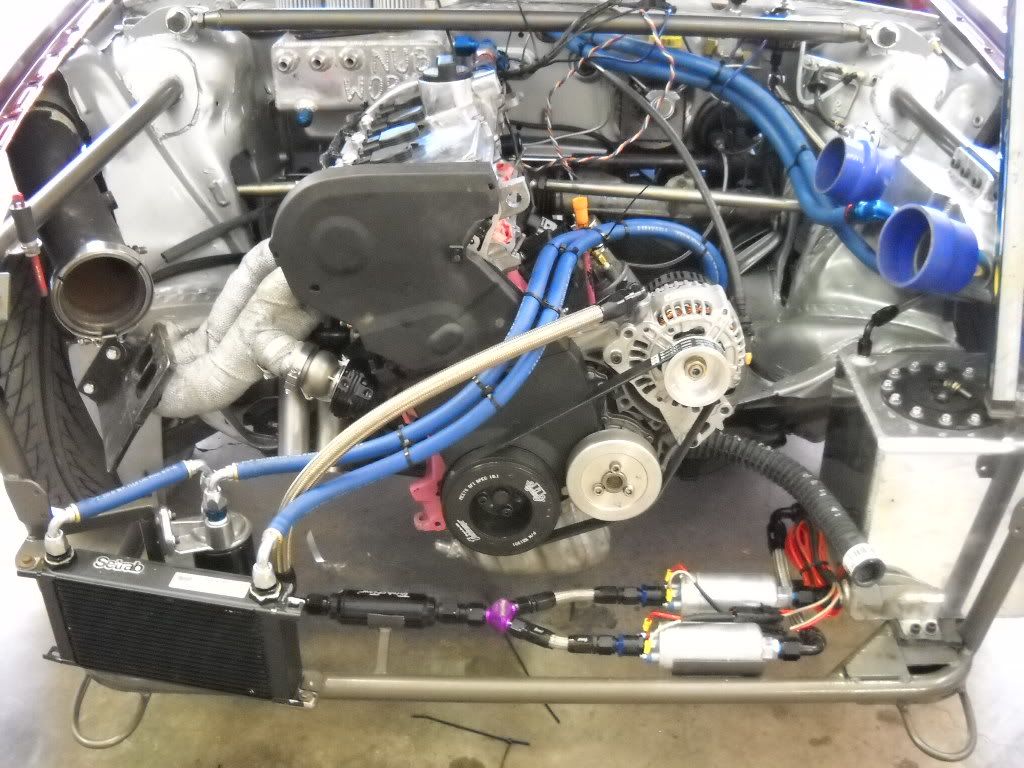

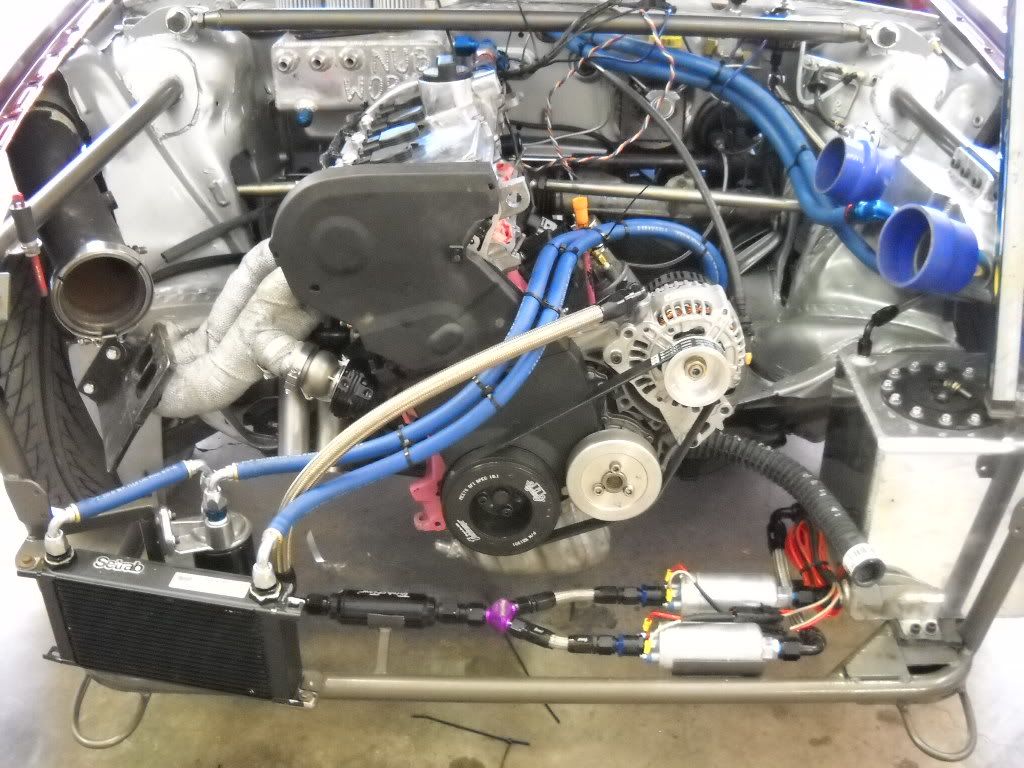

clutch cover.

water pump.

coolant port off end of the head.

alternator bracket.

alternator.

belted up. spent a good hour timing the thing.... and the Fluidampr, Johnny (zerb) sent me his own so i could get this up and going this weekend. nice guy, that Johnny

oh yeah, and i really like Nordlocks....

going in for the final time. until the big motor is here and then later will swap out. but only after i make a few passes on the car with this one.

and its in. home sweet home, for now.

spent a few hours doin stuff finally WOOWOO!!!!

and its no wife-child weekend, so this will be running veeeerrrrrryyyy soon.

starting point.

flywheel. mmmm, aluminum twin disc clutch setup. SF! rated. mmmm.

clutch cover.

water pump.

coolant port off end of the head.

alternator bracket.

alternator.

belted up. spent a good hour timing the thing.... and the Fluidampr, Johnny (zerb) sent me his own so i could get this up and going this weekend. nice guy, that Johnny

oh yeah, and i really like Nordlocks....

going in for the final time. until the big motor is here and then later will swap out. but only after i make a few passes on the car with this one.

and its in. home sweet home, for now.

-

autoxtrëm

i hope you drilled the crank pulley and installed dowel pin, with the power you are gonna make and the fact that the damper is heavier then stock adds stress to the keyway.. we broke 2 keyway on the drag car and the head don't like that. installed tool steel pin and problem solved.

get that thing started Aaron :-)

get that thing started Aaron :-)

-

zerb

-

HT Motorsport

- Posts: 350

- Joined: Wed Feb 27, 2013 11:56 am

-

derrish_vulf

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

thanks all.....

we have an experiment of sorts going with this dowel-the-crank.....

we had a chit-chat with a number of smart people about this, and it is not done to this motor. but the current theory is that this bolt gets tightened to the fear-of-god level.... and it takes just that to remove it. which is the point that it starts to shear the key on the gear. and this can happen while tightening this bolt unsupported. how many people use the biggest air impact they can find? or the big breaker bar with a 6 foot pipe extension? think about the hammer-action of an impact gun.

so catch up just a little and feel free to offer input.

there is a special tool that is made to tighten this gear onto the crank shaft. it bolts to 3 of the 4 bolt holes, and has a place for a 1/2" drive ratchet or breaker to hold it from turning the crank. both gears i have are twisted at the key-piece, a little. but it is twisted the wrong way to have happened by the motor running. how many people actually use this tool to tighten the bolt? not many i surmise. the theory is that the key-part of that gear gets damaged in tightening or loosening of the crank bolt. there is no stress or shockload to this gear, nor overloading of it. UNLESS you are supercharged. a SC setup adds stress and load to this gear, but not a normal car.

so, you guys can take that as you will, today and now it is neither here nor there. this motor does not have a pinned crank gear.

here is the tool: http://www.costplustools.com/Schley-676 ... _7271.html

we have an experiment of sorts going with this dowel-the-crank.....

we had a chit-chat with a number of smart people about this, and it is not done to this motor. but the current theory is that this bolt gets tightened to the fear-of-god level.... and it takes just that to remove it. which is the point that it starts to shear the key on the gear. and this can happen while tightening this bolt unsupported. how many people use the biggest air impact they can find? or the big breaker bar with a 6 foot pipe extension? think about the hammer-action of an impact gun.

so catch up just a little and feel free to offer input.

there is a special tool that is made to tighten this gear onto the crank shaft. it bolts to 3 of the 4 bolt holes, and has a place for a 1/2" drive ratchet or breaker to hold it from turning the crank. both gears i have are twisted at the key-piece, a little. but it is twisted the wrong way to have happened by the motor running. how many people actually use this tool to tighten the bolt? not many i surmise. the theory is that the key-part of that gear gets damaged in tightening or loosening of the crank bolt. there is no stress or shockload to this gear, nor overloading of it. UNLESS you are supercharged. a SC setup adds stress and load to this gear, but not a normal car.

so, you guys can take that as you will, today and now it is neither here nor there. this motor does not have a pinned crank gear.

here is the tool: http://www.costplustools.com/Schley-676 ... _7271.html

-

zerb

-

fasterthenrs2

You are 100% correct, key ways get disturbed using impact guns to undo or TQ middle bolt with out supporting that correctly. I think I have done 100+ crank gears I usually unzip them with impact gun throw old gear out install new gear tq to factory spec using factory tools and when it is tq down key way those nothing to support gear.

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

and i am now going out to wrench.

but i looked at this lil calculator and i have good hopes i know its a calc, but it gives a guesstimate LOL....

i know its a calc, but it gives a guesstimate LOL....

http://www.letstorquebhp.com/calculator.asp

but with 2200 pounds, and only 550 BHP (not AWHP) with AWD =

Power at Flywheel (BHP) : 550

Weight without Driver (KG) : 1000

Power to Weight Ratio (BHP Per Ton) : 558.83

0 - 60 (Secs) : 2.69

0 - 100 (Secs) : 6.55

60 - 100 (Secs) : 3.87

Quarter Mile (Secs) : 11.14

Terminal Speed (MPH) : 130.35

Drag Strip Quarter Mile (Secs) : 10.74

Drag Strip Terminal Speed (MPH) : 134.99

but i looked at this lil calculator and i have good hopes

i know its a calc, but it gives a guesstimate LOL....

i know its a calc, but it gives a guesstimate LOL....http://www.letstorquebhp.com/calculator.asp

but with 2200 pounds, and only 550 BHP (not AWHP) with AWD =

Power at Flywheel (BHP) : 550

Weight without Driver (KG) : 1000

Power to Weight Ratio (BHP Per Ton) : 558.83

0 - 60 (Secs) : 2.69

0 - 100 (Secs) : 6.55

60 - 100 (Secs) : 3.87

Quarter Mile (Secs) : 11.14

Terminal Speed (MPH) : 130.35

Drag Strip Quarter Mile (Secs) : 10.74

Drag Strip Terminal Speed (MPH) : 134.99

:woowoo: :woowoo: OMG get to wrenching!!! cant wait to see it running

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

lunch break. been driving all around this morning, getting last minute crap. probably do the same tomorrow. hungry, seems i forgot to eat today :slap:

and the ADHD factor is on HIGH today. may have to go take a pill.... i will start something, then move to something else, then back, and on to yet another, and back.

just so much to do.... doubt i fire it today, but we will see.

oil lines completed and mounted. TB cover on.

and the exhaust manifold is FINAL MOUNTED. valve cover as well. am going to do anything that needs done below, like the starter wiring, etc before i put on the VC breather hoses. i REALLY want a shot or two of this thing completely together with no fenders and front bumper on it. thats a little work to pull it all apart. skirts have to come off, etc. but i think tubed out open front end will look pretty damned wicked.

and the ADHD factor is on HIGH today. may have to go take a pill.... i will start something, then move to something else, then back, and on to yet another, and back.

just so much to do.... doubt i fire it today, but we will see.

oil lines completed and mounted. TB cover on.

and the exhaust manifold is FINAL MOUNTED. valve cover as well. am going to do anything that needs done below, like the starter wiring, etc before i put on the VC breather hoses. i REALLY want a shot or two of this thing completely together with no fenders and front bumper on it. thats a little work to pull it all apart. skirts have to come off, etc. but i think tubed out open front end will look pretty damned wicked.