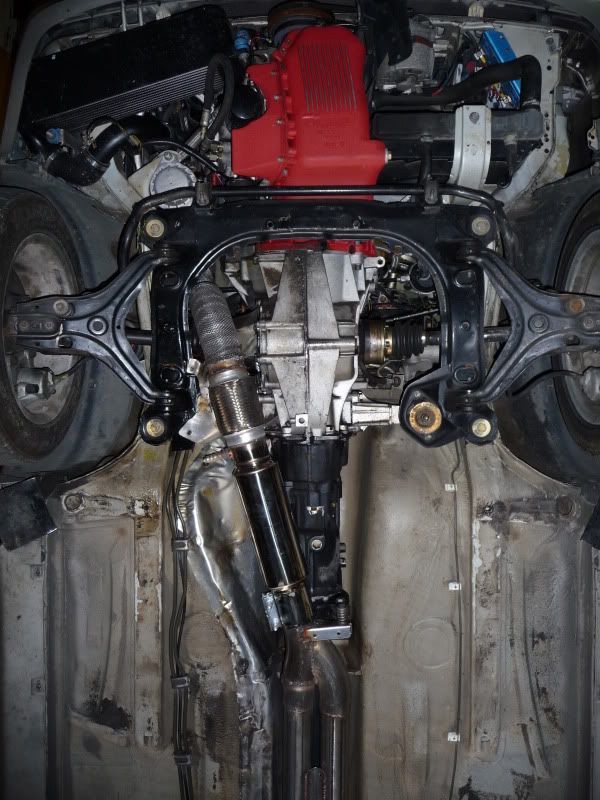

Derracudas zermatt 20vt,6spd, 351awhp - July 4th drive vid

-

derracuda

-

WAUG0806

-

derracuda

-

Hybrid_Hatch

-

derracuda

i'm not sulking. i have a time crunch... i'm on the horn now to get everything lined up to get her back together. i want to show and race the car at the pacific waterland show again this year in sept.

i have a header to build

downpipe to build

intake manifold to build

intercooler to finish

AAN harness to wire up

interior to install

flywheel, trans, clutch master, slave, and line to install

and now the engine to repair...

i think if i concentrate, i can do it. i think that's all i need to do...

i have a header to build

downpipe to build

intake manifold to build

intercooler to finish

AAN harness to wire up

interior to install

flywheel, trans, clutch master, slave, and line to install

and now the engine to repair...

i think if i concentrate, i can do it. i think that's all i need to do...

-

death 4kqt

-

derracuda

oh shit noooooooooooo omg derek

yes you have a long list but from the past 50!!!! pages before this, ive seen nothing short beautified insanity, truly amazing work.

so a small head rebuild on some valves and you should be ready to go, ah well and all the other stuff listed, but think east task should be way easier than all the 5k dash parts right? yea

yes you have a long list but from the past 50!!!! pages before this, ive seen nothing short beautified insanity, truly amazing work.

so a small head rebuild on some valves and you should be ready to go, ah well and all the other stuff listed, but think east task should be way easier than all the 5k dash parts right? yea

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

derracuda wrote:well, in the modified words of smokey the bear, you can help retroactively prevent dereks broken car by visiting the swapmeet section and perusing a long list of various goods that need a new home

derracuda wrote:

how much for a d-cuda custom exhaust

:jawdrop: :jawdrop: :jawdrop:

:heart:

:heart:24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

-

HT Motorsport

- Posts: 350

- Joined: Wed Feb 27, 2013 11:56 am

derracuda wrote:i'm not sulking. i have a time crunch... i'm on the horn now to get everything lined up to get her back together. i want to show and race the car at the pacific waterland show again this year in sept.

i have a header to build

downpipe to build

intake manifold to build

intercooler to finish

AAN harness to wire up

interior to install

flywheel, trans, clutch master, slave, and line to install

and now the engine to repair...

i think if i concentrate, i can do it. i think that's all i need to do...

Have you ran these plans by the soon to be wife yet? I've noticed that as of late you don't spend near as much time on MG as you used to. I was thinking I might even have half a chance at some of the swap meet stuff now, but looking at that list you might just not have time for MG anymore.

-

a_CQ

-

derracuda

what is that piece of metal, the spacer that slides on the stud for the timing belt cover?

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

-

derracuda

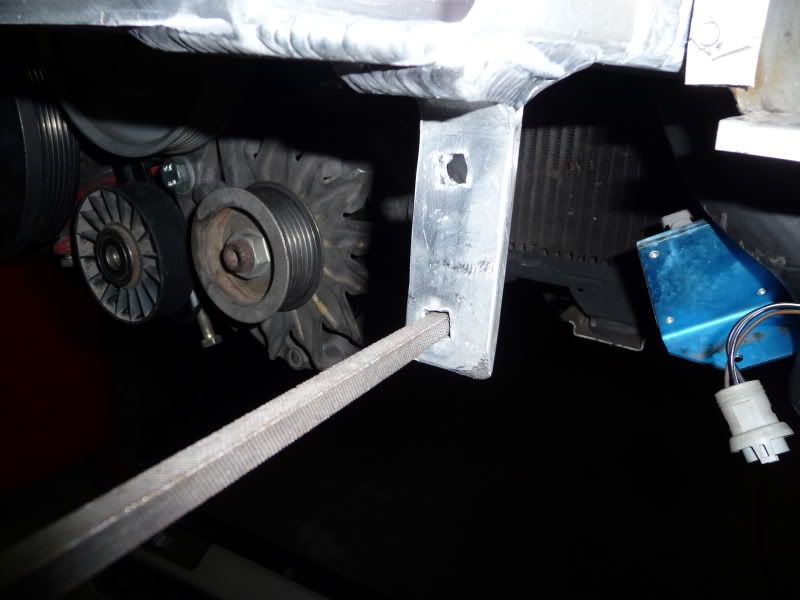

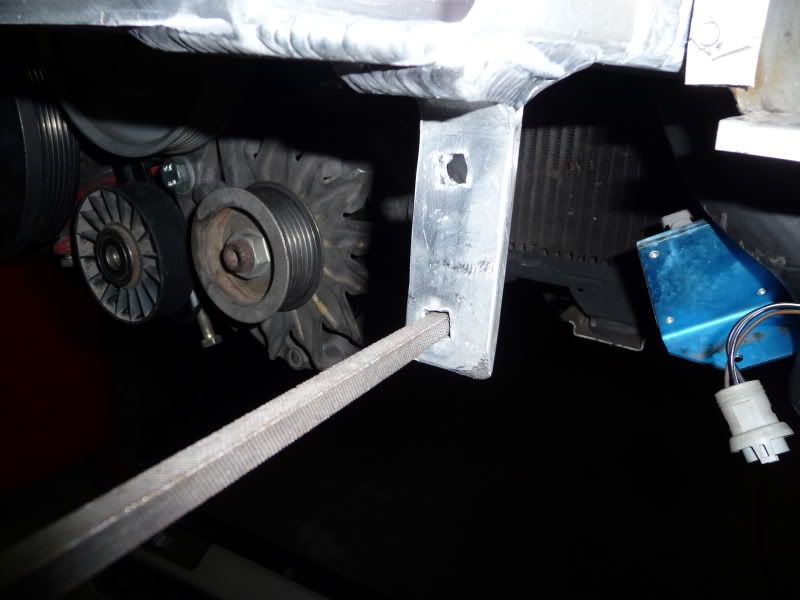

that piece of metal..... it's part of the sheetmetal from behind the bumper, under the SS beauty trim.

anyhow, enough of that, i wanna think about the IC otherwise i'll get sidetracked and drop the ball on my big fab projects here. the repairs are straight forward, this custom stuff takes concentration and creative thinking, which is what i need to produce from my mind

intercooler mounting... i had some carriage bolts left over from the old A8 parts car and i thought, huh, this would make mounting and unmounting the IC easy. only need to hold one tool to undo it. i drilled the holes and stuck the bolts through...

then sucked them through..

then pulled it apart and carefully filed the holes square so that the bolts aren't a super tight fit, but they won't rotate now when you tighten the nut from the backside.

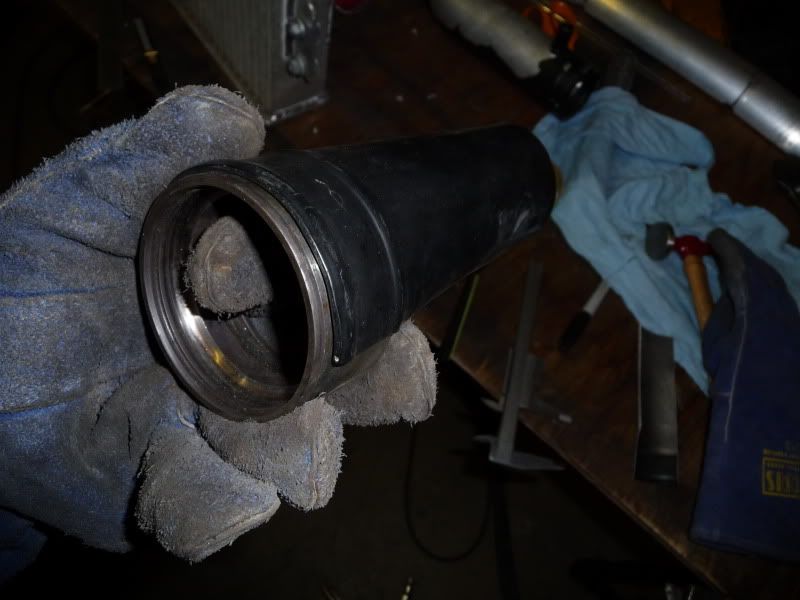

end tanks!

before we go on, i did a little googling of end tank design, and came across this, which i found interesting

it's an F1 car piece. super thin tanks, but blended out nicely. i need the clearance of a low tank, so i'm going to make a slight compromise to get the fitment i need, although my tanks look to be considerably larger than these.

I cut out the end plates and then formed them a bit on a block of wood so they fit better. my welding skills are sometimes better... sometimes not. still learning.

i have a box of misc pipes to rummage through and the ones i'll be using here are volvo bits.

note to self, and everyone else welding aluminum who doesn't do it for a living... FIT EVERYTHING PERFECTLY

it's a pain in the neck to weld up gaps if you aren't super proficient with the welder.

this is the general idea for the inlet

i cut the elbow out to give it a nice inlet angle and point it in the right direction on the car

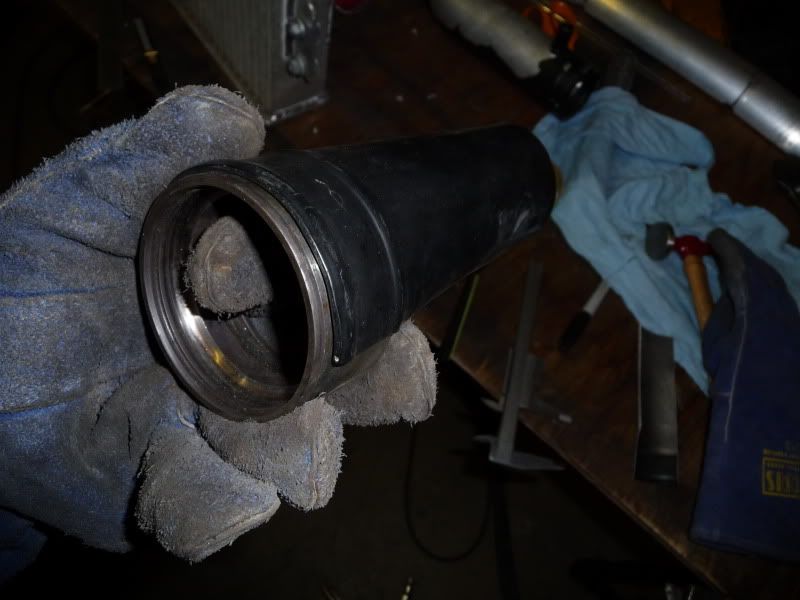

i'm fitting 2" pipe to a 3" round endcap, so i had to open up and form it a little. turns out 82mm bearing shells work great for this!

then set it all in place and mark the main tank

carefully cut it out

and how it should hopefully all turn out

anyhow, enough of that, i wanna think about the IC otherwise i'll get sidetracked and drop the ball on my big fab projects here. the repairs are straight forward, this custom stuff takes concentration and creative thinking, which is what i need to produce from my mind

intercooler mounting... i had some carriage bolts left over from the old A8 parts car and i thought, huh, this would make mounting and unmounting the IC easy. only need to hold one tool to undo it. i drilled the holes and stuck the bolts through...

then sucked them through..

then pulled it apart and carefully filed the holes square so that the bolts aren't a super tight fit, but they won't rotate now when you tighten the nut from the backside.

end tanks!

before we go on, i did a little googling of end tank design, and came across this, which i found interesting

it's an F1 car piece. super thin tanks, but blended out nicely. i need the clearance of a low tank, so i'm going to make a slight compromise to get the fitment i need, although my tanks look to be considerably larger than these.

I cut out the end plates and then formed them a bit on a block of wood so they fit better. my welding skills are sometimes better... sometimes not. still learning.

i have a box of misc pipes to rummage through and the ones i'll be using here are volvo bits.

note to self, and everyone else welding aluminum who doesn't do it for a living... FIT EVERYTHING PERFECTLY

it's a pain in the neck to weld up gaps if you aren't super proficient with the welder.

this is the general idea for the inlet

i cut the elbow out to give it a nice inlet angle and point it in the right direction on the car

i'm fitting 2" pipe to a 3" round endcap, so i had to open up and form it a little. turns out 82mm bearing shells work great for this!

then set it all in place and mark the main tank

carefully cut it out

and how it should hopefully all turn out