Derracudas zermatt 20vt,6spd, 351awhp - July 4th drive vid

-

HT Motorsport

- Posts: 350

- Joined: Wed Feb 27, 2013 11:56 am

-

teamplatto

audi90quattro10v wrote:it just seems like a super tight ratio, guess im just used to the 10 turner

My rally car is doing 1.5 lock to lock, easy to drive and when you have a sequence of turn to make, it just helps you keep your hands at the same place on the steering wheel, concentration is the key :bashtard:

-

cuatrokoop

- Posts: 271

- Joined: Thu Mar 07, 2013 11:27 pm

- Location: Findlay, OH

-

derracuda

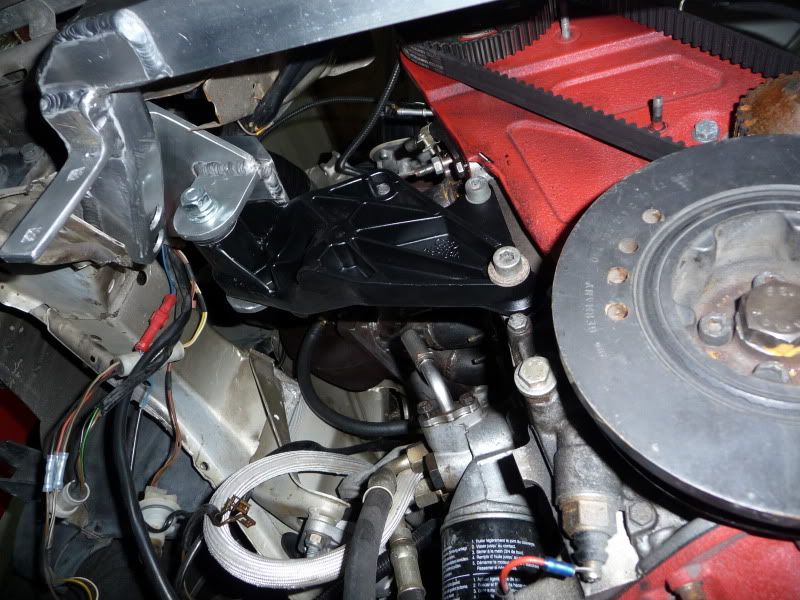

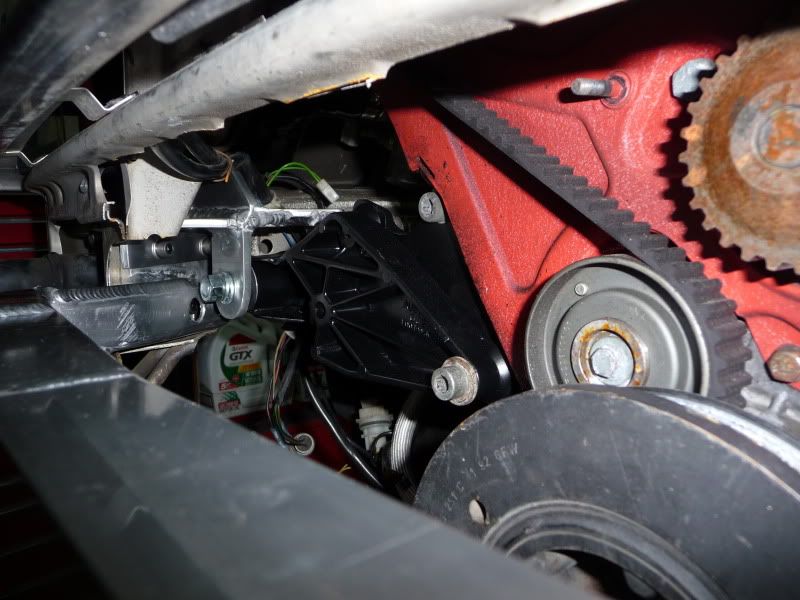

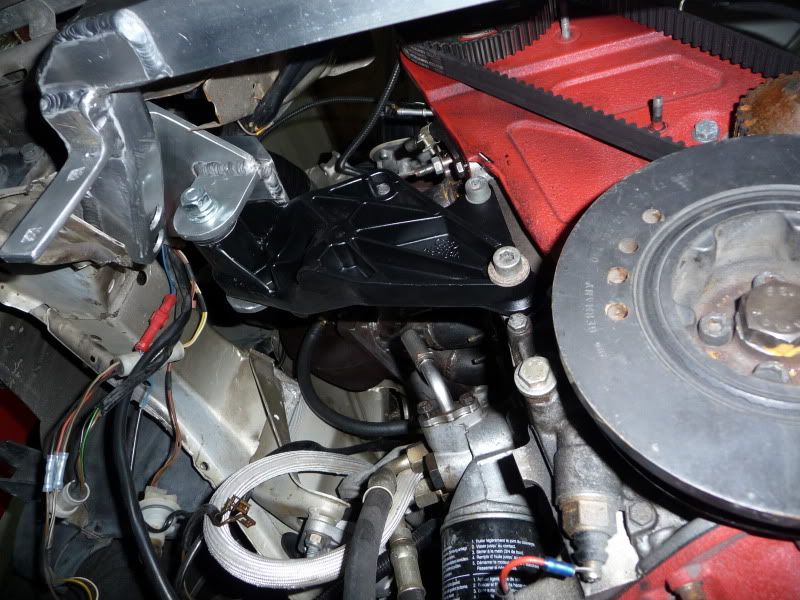

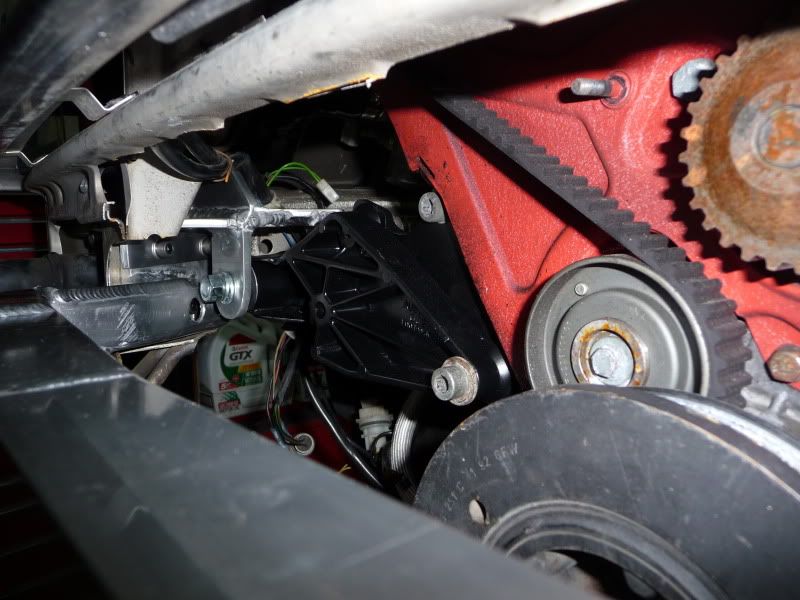

got some more done... the other half of the engine snub bracket needed to be completed, and i had aluminum stock just taking up space...

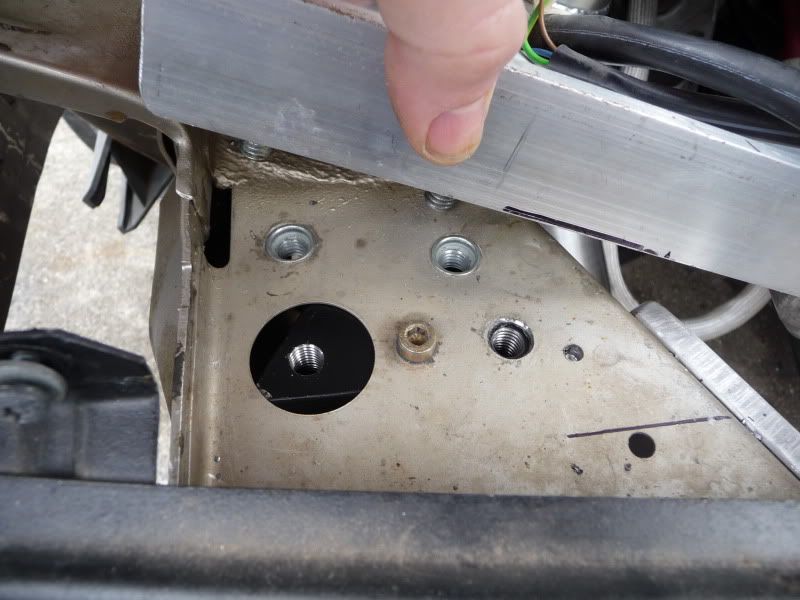

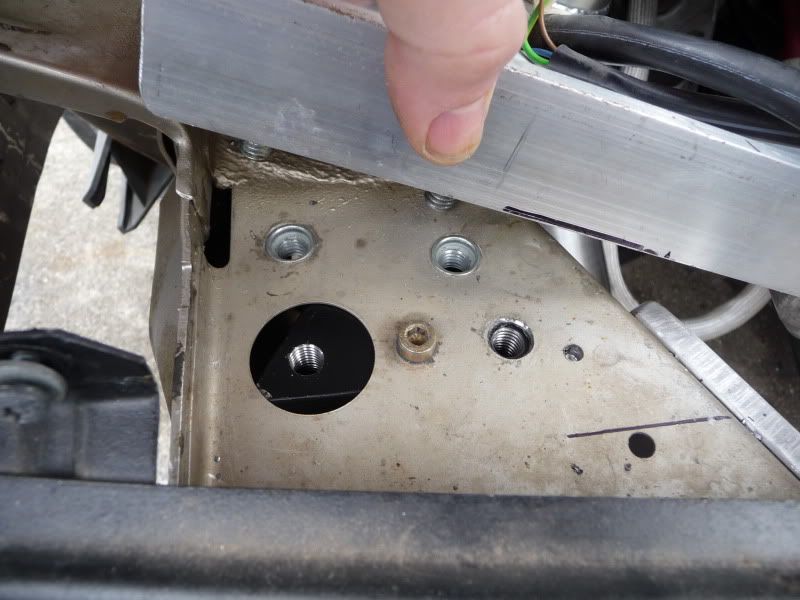

this portion of the snub bracket sits on the frame side. i wanted it to be easy to take off, so that means nut inserts into the frame rail, or some kinda plate from underneath.. and i went with both. i can't fit a whole plate in there through the bumper shock hole, so the rear two holes are nut inserts, the front two are threaded into a triangle shaped piece of 5/8" plate, held up to the underside of the top of the frame rail with a little allen bolt

the allen bolt sits flush in the bracket and also serves as an alignment dowl when fitting. works out really nice too!

this is the rest of the bracket

it bolts up on the outside of the new crossmember and is all sandwiched together. 6 bolts in all holding the snubber to the frame rail

i painted the bracket that bolts to the engine matte black, and sanded, then polished with steel wool, the piece i welded up, the painted it with clear. youc an also see the ears have been rounded off and everything smoothed out on the edges

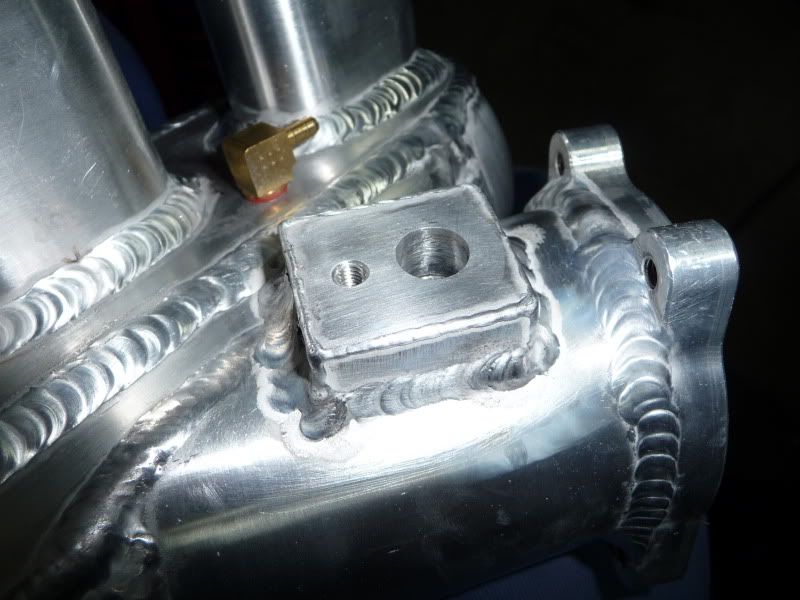

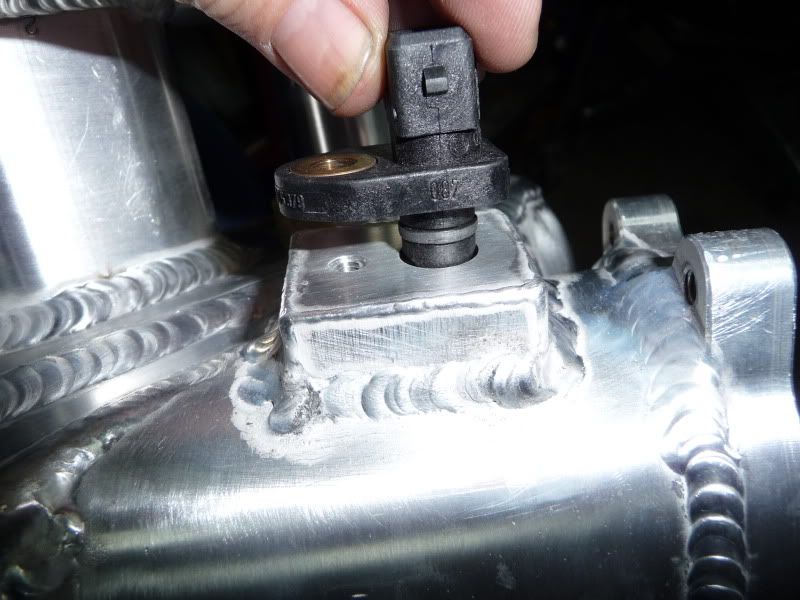

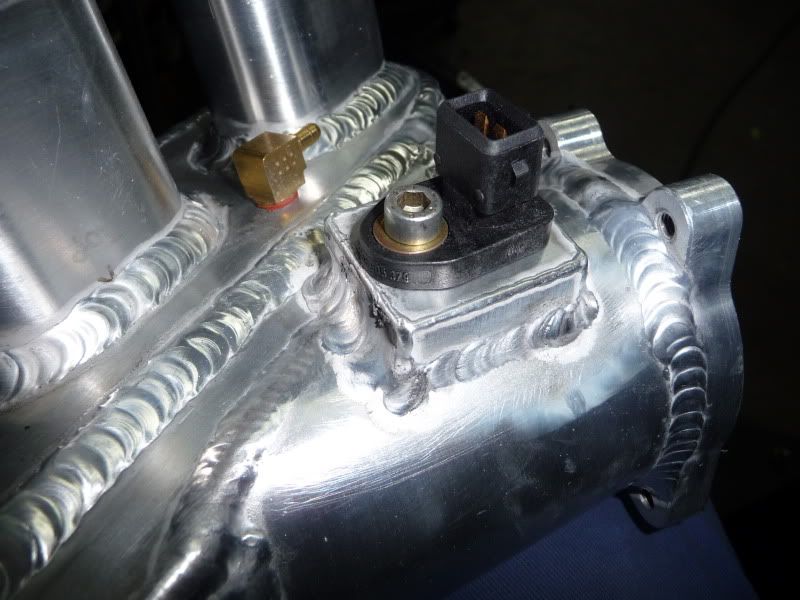

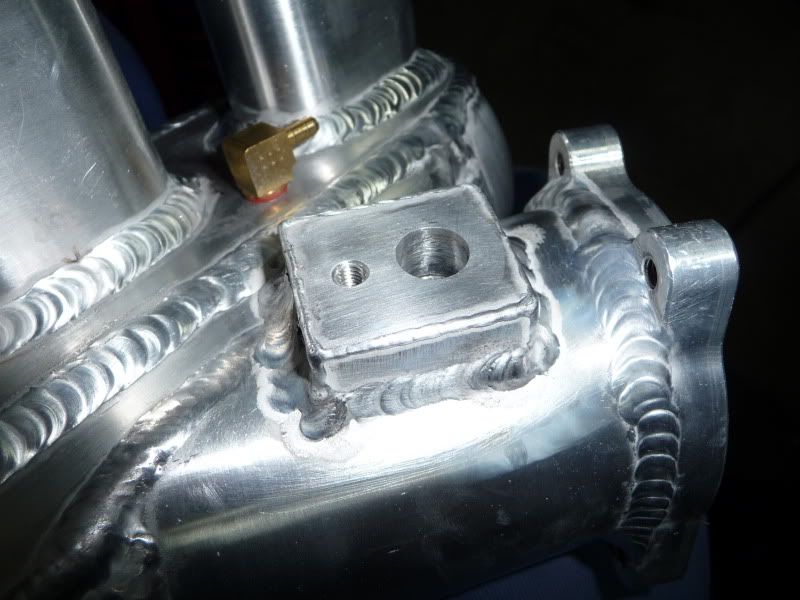

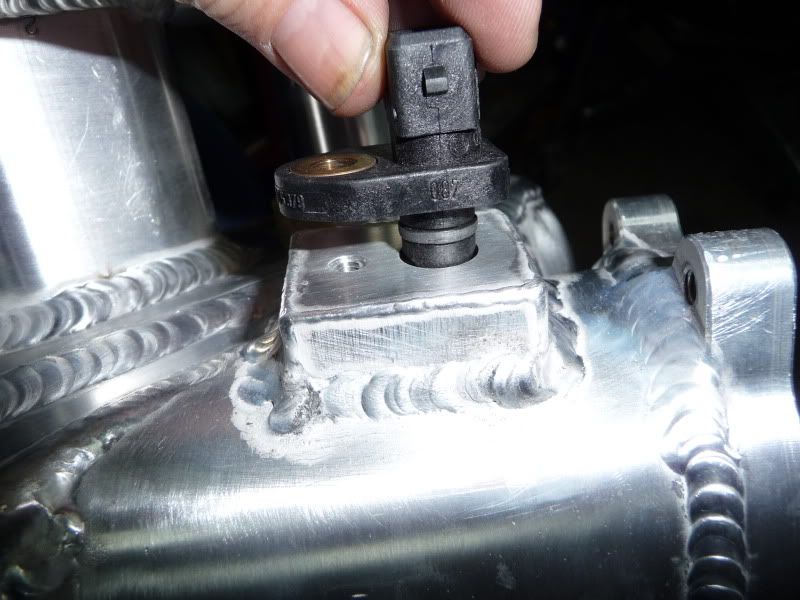

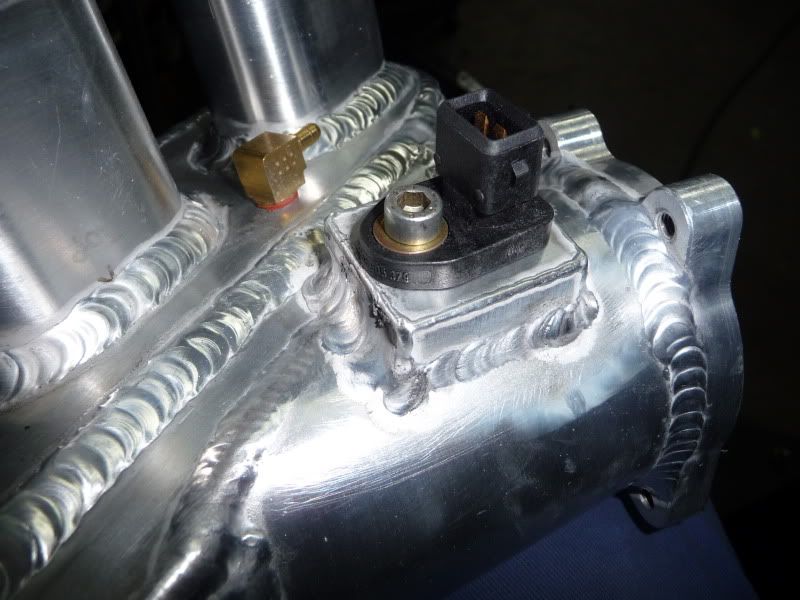

the last thing i did tonight was weld up the IAT port. found a block of aluminum and drilled it to fit, sanded the inside smooth for a nice sealing surface, and then tapped the little hole and welded er' up.

yesss... two more things done on my list 8) i've also figured out a sweet fuel pressure regulator setup. Ross Machine has these babies...

http://www.rossmachineracing.com/fuelpresregadapt.html

fits a 4bar newer super compact regulator 8) and i need a couple fittings for my fuel lines.

i also figured out what i need for my oiling system and will be stopping by a hydraulics shop soon to get that sorted out.

i can almost hear it running.... *drools*

this portion of the snub bracket sits on the frame side. i wanted it to be easy to take off, so that means nut inserts into the frame rail, or some kinda plate from underneath.. and i went with both. i can't fit a whole plate in there through the bumper shock hole, so the rear two holes are nut inserts, the front two are threaded into a triangle shaped piece of 5/8" plate, held up to the underside of the top of the frame rail with a little allen bolt

the allen bolt sits flush in the bracket and also serves as an alignment dowl when fitting. works out really nice too!

this is the rest of the bracket

it bolts up on the outside of the new crossmember and is all sandwiched together. 6 bolts in all holding the snubber to the frame rail

i painted the bracket that bolts to the engine matte black, and sanded, then polished with steel wool, the piece i welded up, the painted it with clear. youc an also see the ears have been rounded off and everything smoothed out on the edges

the last thing i did tonight was weld up the IAT port. found a block of aluminum and drilled it to fit, sanded the inside smooth for a nice sealing surface, and then tapped the little hole and welded er' up.

yesss... two more things done on my list 8) i've also figured out a sweet fuel pressure regulator setup. Ross Machine has these babies...

http://www.rossmachineracing.com/fuelpresregadapt.html

fits a 4bar newer super compact regulator 8) and i need a couple fittings for my fuel lines.

i also figured out what i need for my oiling system and will be stopping by a hydraulics shop soon to get that sorted out.

i can almost hear it running.... *drools*

-

subvertdesign

Gettin fancy there Derek. Progress is looking great as usual! Still using the TA-185 for the AL welding?

I noticed on my AAN intake manifold there's a smoothed bump inside in front of the IAT that sort of blocks the direct flow to the wires. Probably helps preserve it a little longer when you're running 90psi :-D

I noticed on my AAN intake manifold there's a smoothed bump inside in front of the IAT that sort of blocks the direct flow to the wires. Probably helps preserve it a little longer when you're running 90psi :-D

- audifreakjim

- Posts: 2142

- Joined: Sun Mar 03, 2013 3:00 pm

-

derracuda

ShavedQuattro wrote:Looks good Derek. The Al welding is getting better too! when is the 01e going in?

thanks! i've had to learn a bit of ambidexterous welding too

the 01E won't be going in until i break this one most likely. it all works fine currently (aside from grinding fourth syncro, but i can live with that for a while longer)

the 01E won't be going in until i break this one most likely. it all works fine currently (aside from grinding fourth syncro, but i can live with that for a while longer)Jared, yes, still using the TA 185... good little machine i tell you. addictive! i put my IM on our shop heater and that gets it up to maybe 130F or so, that helps a lot in getting it to puddle nicely. i also figured out how to use the pulse settings... that's slick!

i got another christmas present this morning. i ordered a 4"-3" 90 degree silicone reducer for the turbo inlet. it was a little long so i trimmed an inch off... fits perfect

-

derracuda

i got the snub bracket all bolted in and started to work on the downpipe last night before i had to leave town again, so.. two more weeks until i can touch it again...

i also sanded, Steel wool polished, and clearcoated the front crossmember, so it's completed. i forgot to take pics, but i made nut plates that go inside the front of the frame rails for the four bolts per side that hold the cross member in. that way i only have to undo the 6mm allen bolts on the backside and don't have to hold any wrenches when taking the crossmember out 8)

i also sanded, Steel wool polished, and clearcoated the front crossmember, so it's completed. i forgot to take pics, but i made nut plates that go inside the front of the frame rails for the four bolts per side that hold the cross member in. that way i only have to undo the 6mm allen bolts on the backside and don't have to hold any wrenches when taking the crossmember out 8)

wow dang, major progress, i need to check this thread more often

loving it, cant wiat to see it back driving again

loving it, cant wiat to see it back driving again

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

-

derracuda

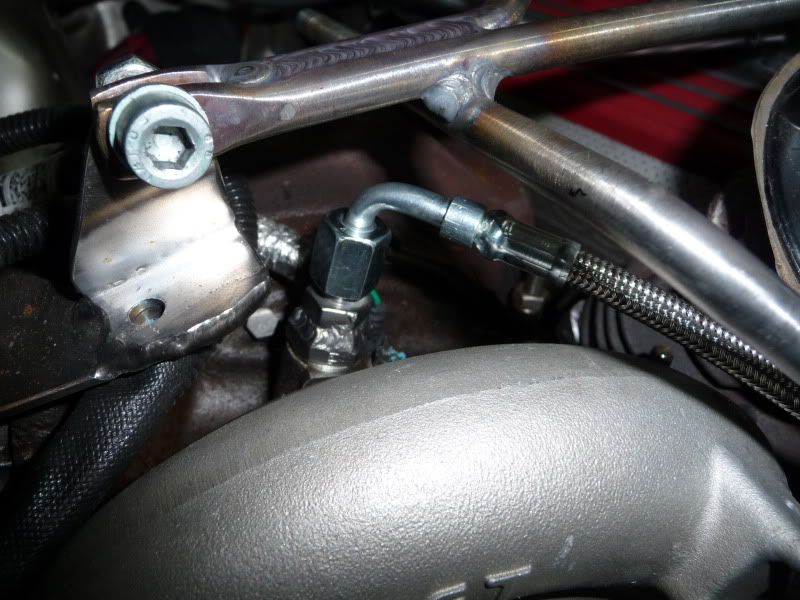

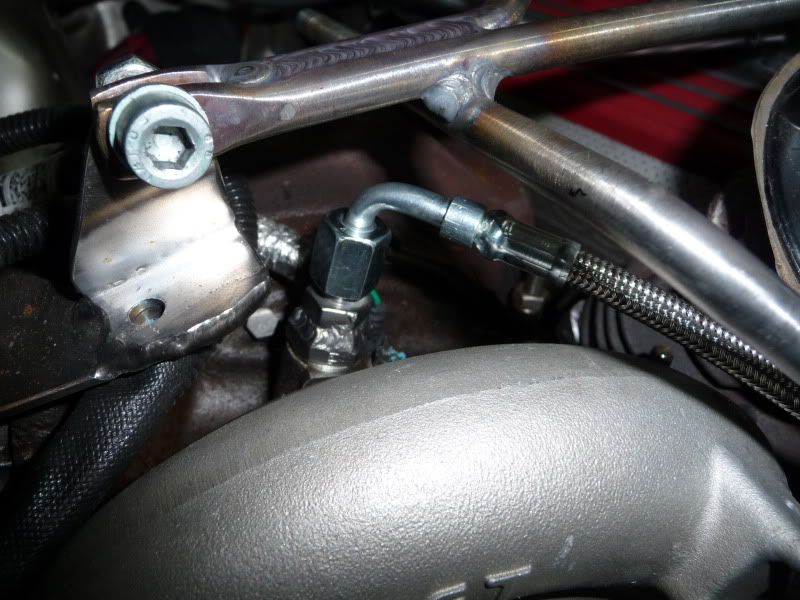

i got a christmas present the other day, the FPR adapter came  and i also had the turbo oil pressure line made up.

and i also had the turbo oil pressure line made up.

i ordered two of the mustang tranny mounts for my engine. i'm going to try just one on the drivers side to keep the intake from jumping and touching the hood, and hopefully with the snubber up front everything will be secured enough, but not so firm it vibrates the car badly.

also awaiting the fuel supply line to me made up that goes to the front of the rail.

and i also had the turbo oil pressure line made up.

and i also had the turbo oil pressure line made up.

i ordered two of the mustang tranny mounts for my engine. i'm going to try just one on the drivers side to keep the intake from jumping and touching the hood, and hopefully with the snubber up front everything will be secured enough, but not so firm it vibrates the car badly.

also awaiting the fuel supply line to me made up that goes to the front of the rail.

-

dubsmith

-

derracuda

back from the holidaze

i went to fit up my turbo oil feedline and as i feared, the two adapters were a bit too tall...

so chop chop!

give it the clamps

and a little weld to make it nice and short

i also decided instead to thread one of these babies in to hook up the line (i decided on -4AN btw)

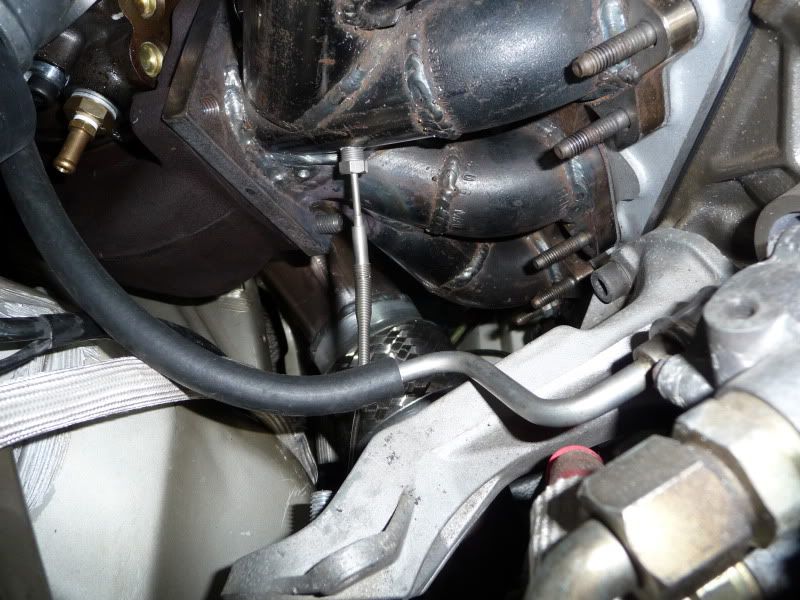

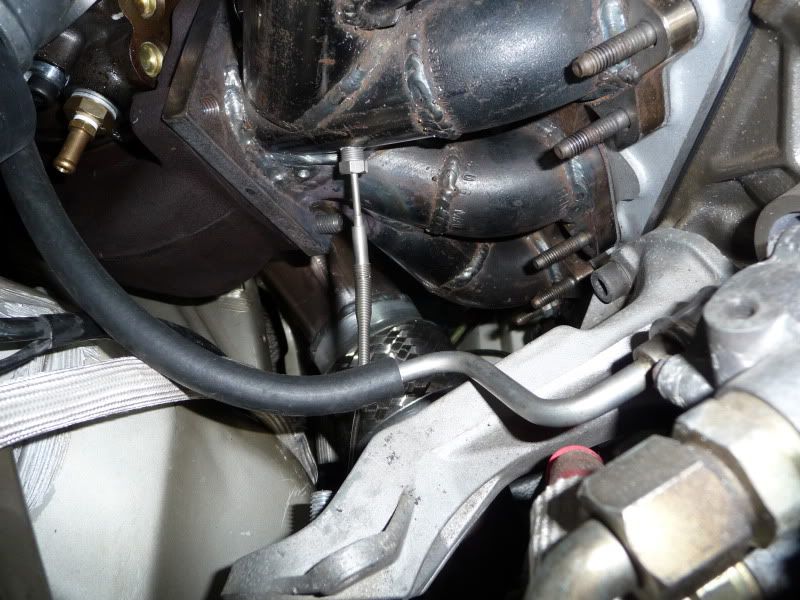

threaded hole for the EGT probe. it sits at a slight rearward angle so as not to impede access to the motor mount arm top nut.

then i finally got the DP made. i hated this part. last night i couldn't get to sleep until 1:30 or so, tossed and turned and then had to get up at 7:30, work, etc, and at the point of day when i was cutting and fitting my brain was working very slowly...

it turned out alright though. i just need to add one more mount to help support it, and then wrap it with some fancy copper header wrap 8)

got the water manifold finished too..

today i got to scratch 6 things off the list..

turbo oil lines (ok, i have to finish the drain line)

turbo coolant lines

downpipe

coolant manifold

egt probe installed

wastegate dump pipe welded

mwuhahaha, i can almost hear it running again!

i went to fit up my turbo oil feedline and as i feared, the two adapters were a bit too tall...

so chop chop!

give it the clamps

and a little weld to make it nice and short

i also decided instead to thread one of these babies in to hook up the line (i decided on -4AN btw)

threaded hole for the EGT probe. it sits at a slight rearward angle so as not to impede access to the motor mount arm top nut.

then i finally got the DP made. i hated this part. last night i couldn't get to sleep until 1:30 or so, tossed and turned and then had to get up at 7:30, work, etc, and at the point of day when i was cutting and fitting my brain was working very slowly...

it turned out alright though. i just need to add one more mount to help support it, and then wrap it with some fancy copper header wrap 8)

got the water manifold finished too..

today i got to scratch 6 things off the list..

turbo oil lines (ok, i have to finish the drain line)

turbo coolant lines

downpipe

coolant manifold

egt probe installed

wastegate dump pipe welded

mwuhahaha, i can almost hear it running again!

:woowoo: :woowoo: :woowoo: so exciting this car is amazing

oem plus my @ss hahahah

oem plus my @ss hahahah

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

-

HT Motorsport

- Posts: 350

- Joined: Wed Feb 27, 2013 11:56 am

-

Longitudinal

- Posts: 107

- Joined: Sun Mar 03, 2013 1:29 am

Derek, did you weld the water mani on the head? If not, I doubt it is even close to being strait anymore. They are terrible to weld on,. They shrink and make it impossible to get a good seal. I would guess no based on the welding glove holding the hot part...

Looks good though. Tig skills are improving!!

Looks good though. Tig skills are improving!!

-

derracuda

Hank, the manifold fits just fine... AFAIK. the flanges are all still flat, and all the fittings still easily fit in the holes. i was careful about not just hammering it with heat when i welded it. i learned how to use the pulse settings on the welder and that's nice

TIG yes. the machine belongs to Aaron (g60freak), he's been graciously loaning it to me, and i've decided as soon as i can raise some extra funds, i'm buying one... i can't live without it.

as to OEM plus, i changed the name. i think it will be appropriate seeing how the car is rather sleeperish and you won't see it coming

TIG yes. the machine belongs to Aaron (g60freak), he's been graciously loaning it to me, and i've decided as soon as i can raise some extra funds, i'm buying one... i can't live without it.

as to OEM plus, i changed the name. i think it will be appropriate seeing how the car is rather sleeperish and you won't see it coming

smiley. Thanks for finding that fpr adapter btw. Just what i need!

smiley. Thanks for finding that fpr adapter btw. Just what i need!