Hanks URQ 2.6L Autopsy

-

pploco

-

Highlander

-

84urq20v

Yo Hank - lookin' good man. Car looked great at urq25. Anyway - regarding the in dash boost gauge - it's pretty useless IMO. Have you considered putting a factory 4kq/CGT in dash temp gauge in there instead? They come in a graduated (each line = 10 degrees C) version and you can get a matching arc'd gas gauge, too - I hear they work fine in an urq even tho the CGT/4kq had smaller tanks. Both have orange needles to boot. See my pic for the temp gauge - I've been too lazy to swap gas gauges. I run my temp gauge of the MFTS - but I'm assuming you can run it off a regular temp sender as the 4kq and CGT didn't have the MFTS...

pic below

Brandon

Attachment ( 14394 ) : IMG_0058.JPG

pic below

Brandon

Attachment ( 14394 ) : IMG_0058.JPG

Thanks Janis!

Check out this version of it that I built for Justin Js car. This should solve the problem of running a street car with 1600cc injectors!!!

Brandon, I dont know how I missed that post of yours. I have since changed out that boost gauge for a temp gauge although I doubt that it will stay in there long. I want to stick my WideBand gauge there so it is in the dash, and then I want to put the gas gauge where the radio was. No one needs to see how much gas they have at a glance, but A/R ratio would be nice!!! 8)

Check out this version of it that I built for Justin Js car. This should solve the problem of running a street car with 1600cc injectors!!!

Brandon, I dont know how I missed that post of yours. I have since changed out that boost gauge for a temp gauge although I doubt that it will stay in there long. I want to stick my WideBand gauge there so it is in the dash, and then I want to put the gas gauge where the radio was. No one needs to see how much gas they have at a glance, but A/R ratio would be nice!!! 8)

-

fasterthenrs2

-

vagrant_mugen

hey hank,

i need a head flange for a 16v(4cyl.) any chance you know where to find one of those??? and know how much?? LMK.

speaking of dual injectors, i was looking at the CBR1000 ITBs i bought, and they have there own set of injectors and a fuel rail, so with a flange like that, and i can have dual sets of injectors too.

i need a head flange for a 16v(4cyl.) any chance you know where to find one of those??? and know how much?? LMK.

speaking of dual injectors, i was looking at the CBR1000 ITBs i bought, and they have there own set of injectors and a fuel rail, so with a flange like that, and i can have dual sets of injectors too.

Wow, This is my first post of the year on my poor URQ project.

Well, I finally decided enough was enough, and I needed to get it back on the road, and enjoy some spring driving before it got too hot. I took it down in November to keep me from rippngit around in the salty roads of Salt Lake City and Park City. It would be a shame to put rust on this rustess car.

So I took it down and used it as a jig to make some manifolds for some friends and customers. I have made 3 of them now for my car, and then people want them, and I end up selling them... Besides not having an IM, I was tired of my breather to relieve crank pressure as well. I did not have the can draining back to the crank, so I was consuming a ton of oil, and if it got too high, it overflowed everywhere. I was not sure I was getting a good vent either, as I was pulling off the rear of the VC, and I think that it was sloshing into my can..

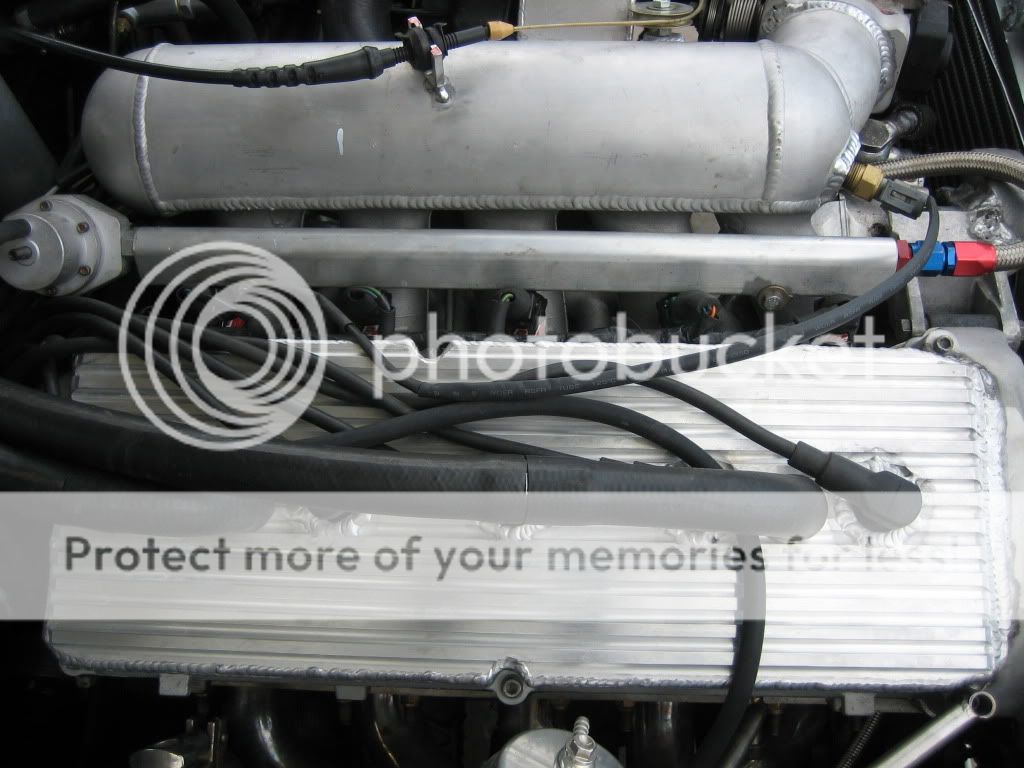

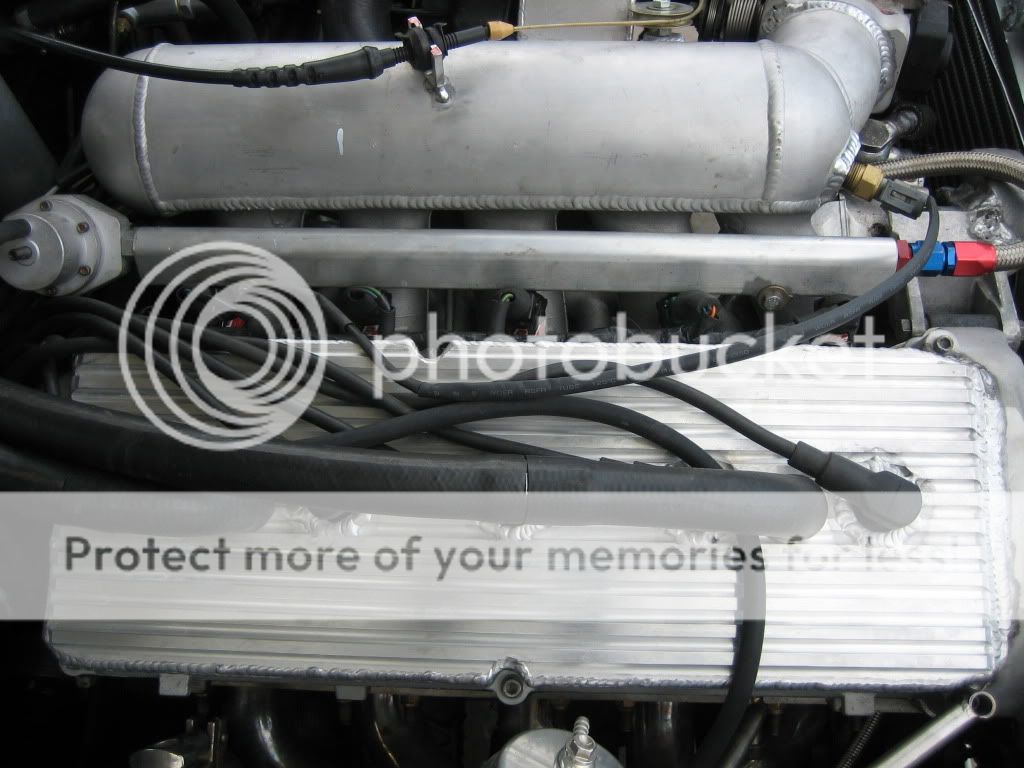

So I went to the drawing boards and decided to make my own valve cover that would seperate 99 percent of the oil, and then I would just have it going into a can to get the remainder. I started with a 7a cover, built up the sides about an inch with plate 6061, lathed extenders for the spark plug holes and deleted the oil fill up location. I then noted carefully where all the oil was sloshing from(mostly the cam lobes) and drilled 1/4" holes where that was not taking place. I put about 40 of them in there. I then put stainless steel wool over the holes and put covers over them to provide yet one more baffle, and trap door the oil had to overcome to even get to the open space where i was pulling a vent off of..

I then found this sweet surplus piece of 6061 extrusion that I wanted to use, so I made the top, and welded in provisions for two 3/4" vents. I used pushlock hose to get from the cover to the can, and I am for now just putting the remainder into the air filter so I dont have to smell it inside the cabin.

So that took care of that problem..

My next complaint with the car was the brakes. I just had g60s on there. They did well in town, and the occasional rip up the canyon, but they got hot fast, and it didnt take much to get them to fade. I could get them to fade going UP the canyon and knew something needed to be done. I had bought some a8 rotors 4 years ago, and before i knew the evil of crossdrilled rotors when I had my 5000. I had them, so I used them, along with the TT stuff. I also had been having problem with the POS bias valve, so i got the Wilwood valve, and did some flare work to make it work. The brakes rock now. They are great brakes!1!!!

Well, I finally decided enough was enough, and I needed to get it back on the road, and enjoy some spring driving before it got too hot. I took it down in November to keep me from rippngit around in the salty roads of Salt Lake City and Park City. It would be a shame to put rust on this rustess car.

So I took it down and used it as a jig to make some manifolds for some friends and customers. I have made 3 of them now for my car, and then people want them, and I end up selling them... Besides not having an IM, I was tired of my breather to relieve crank pressure as well. I did not have the can draining back to the crank, so I was consuming a ton of oil, and if it got too high, it overflowed everywhere. I was not sure I was getting a good vent either, as I was pulling off the rear of the VC, and I think that it was sloshing into my can..

So I went to the drawing boards and decided to make my own valve cover that would seperate 99 percent of the oil, and then I would just have it going into a can to get the remainder. I started with a 7a cover, built up the sides about an inch with plate 6061, lathed extenders for the spark plug holes and deleted the oil fill up location. I then noted carefully where all the oil was sloshing from(mostly the cam lobes) and drilled 1/4" holes where that was not taking place. I put about 40 of them in there. I then put stainless steel wool over the holes and put covers over them to provide yet one more baffle, and trap door the oil had to overcome to even get to the open space where i was pulling a vent off of..

I then found this sweet surplus piece of 6061 extrusion that I wanted to use, so I made the top, and welded in provisions for two 3/4" vents. I used pushlock hose to get from the cover to the can, and I am for now just putting the remainder into the air filter so I dont have to smell it inside the cabin.

So that took care of that problem..

My next complaint with the car was the brakes. I just had g60s on there. They did well in town, and the occasional rip up the canyon, but they got hot fast, and it didnt take much to get them to fade. I could get them to fade going UP the canyon and knew something needed to be done. I had bought some a8 rotors 4 years ago, and before i knew the evil of crossdrilled rotors when I had my 5000. I had them, so I used them, along with the TT stuff. I also had been having problem with the POS bias valve, so i got the Wilwood valve, and did some flare work to make it work. The brakes rock now. They are great brakes!1!!!

-

cuatrokoop

Derek, I have been working on a cad drawing for an imsa cover. The drawing is the easy part.... the material would expensive for that chunk, and the machining would be harder...

Dave, the car is down in provo....

Eric, No, those are mine, but my Dad does have a set as well!!! he has convinced you that my URQ is his huh?

my two whips together for a v10 40vt twin turbo shot

Dave, the car is down in provo....

Eric, No, those are mine, but my Dad does have a set as well!!! he has convinced you that my URQ is his huh?

my two whips together for a v10 40vt twin turbo shot

-

glibobbo21

- Posts: 659

- Joined: Wed Feb 27, 2013 11:51 am

so how do i get one of those manis made for me? :-D

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

-

death 4kqt

wheres the line start, and hey utah boys i work for a ski company hook me up and i hook u ups!!!!

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

-

death 4kqt

hey whoa, wasnt cutting, i just couldnt find the line ahha but really were you trying to get one too?

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

-

death 4kqt

Looks awesome Hank! Nice work as usual!

Looks awesome Hank! Nice work as usual!