I felt inspired this evening/morning by Sam's marathon post....

Well, the car is back on the road and ripper status again. It is a really long story that involves 4 head gaskets and head removals over the last 6 weeks, but I am finally back in action. Long story short, I had a piston hit a head, and chew up a bearing. Now the question is what came first, the chicken or the egg? Piston to head clearance of that motor was about .035" with a standard mls gasket. This should be enough, but there was some contact. A bearing going would put enough slop so that at 8500, the piston may be able to reach the head. This is what I believed the first time when I just slapped in a new head gasket. This is a theroy, but later on I found that I like to reject it in favor of the idea that the wiseco's rock a tremendous amount combined with a shady block. The old WR block was not flat, and about .009" twisted(yes, an I5 twisted torsionally) corner to corner, with the high spot being the #1 cylinder(aka the cylinder with contact.). Sure, you guys are thinking that the back corner would be high then as well if this is correct. It was high, but the back corner would not be in the squish, and that tolerance is another +.030 so there wasn't any contact. Anyway, it hit. If a piston hits a head at 8500, the rod bearing has no freaking chance whatsoever.

I figured that hte water in the #1 bore was due to the head lifting when the contact happen. So I just threw another headgasket in, changed the bearing on the bad cylinder, and put it back together.. <drumroll> I still had a leaky #1 upon reassemble. I figured that the poor surface finish on the deck was to blame. I had to weld up a passage to use the WR block with the 20v head, and the file must have been too rough for hte MLS I figured.

Explaination of the block twisting? It is the WR block. For those who have not seen the block up close, it has a few differences but the notable one in my case is the lack of webbing on the block. For whatever reason, Audi decided the newer MC and later 7a,3b and aan blocks needed more webbing.. Why? I'll speculate it was due to testing done in Rally

I measured the piston to wall clearance on that motor( the only thing I really did not measure when putting it together, due to not having a bore gauge in the barn that the assembly took place in). It was a staggering .008" compared to the .0025-.0035" that Wiesco recommends. In addition, the bores were scored on the sides. This is text book for piston rock scoring. Now how did that get opened up that much? I think the "good ol boy" machine shop doing old school stuff heard piston to wall clearance and used the hold hotrod reference as .035" on each side of the piston.

So what to do? I got a very low mile AAN block in with plans to just swap my balanced 81mm assembly into the bores and call it a day. The problem was that this block was just a tad too warn despite 5 digit mileage. It was at about .0045, and I wanted a clean motor. I thought about coating hte pistons, but I just did not have time with a new baby and 18 credits in my Senior year of college. I got new rings for the 3b pistons, ordered a second set of rods( I didn't want to split up my balanced Scat/Wiseco assembly), and threw that sucker back together with arp mains and head studs. I hot tanked the block, decked the block .003 to make it flat, ball honed the block and installed a new check valve. I did not take the time/expense to balance the motor, mostly because the time factor, but also because I was curious as to how a stock motor with rods thrown in feels.

I got it all back together the sorry sucker still was leaking at #1 still. &^%*%^#$ The deck had a reflection!!! The head had been decked with a similar mirror finish!! What gives? It has to be the damn head!! I took the head off again, and sure enough, the #1 intake port showed signs of water/antifreeze. I can't see any cracks or damage on this freshly rebuilt and ported head. Didn't matter, I was not about to put it back on for a 4th head gasket expense. I still don't know where it is cracked.

I started to prep a head. The head I used was the original head I used when going 20vt, and the head that saw the infamous melt down in 2008 when an injector stuck. It was also a ported head, but had some war wounds from the detonation that occured at 30psi and 600cc/1000ccs of fuel. I welded up the wounds and spent an hour blending the combustion chamber, and sent it to the machine shop with the charge to mow out .015" to get rid of the damage. I figure that I am committed at this point to run e85, so why not try a bit more compression. I threw my high rate springs from the cracked heads in with a quick valve jobs(thanks dad for the awesome valve cutting tools!! They work great!!!) and slapped that bad boy back on.

At last, the thing is back in business as of a couple of weeks ago.. After 200 miles of break in at 22psi and compression numbers of 165psi across the board, I finally raised the wick late last night to 28ish... The thing rips. The high compression is awesome. I figure a static compression ratio of around 9.8:1 considering the .019" of shave work I did, and I can completely tell the difference coming form 8:1 pistons. First of all, spool has decreased another 150rpm, and off boost is very, very nice. Figure that this motor is every bit as open as a stock 7a car and I even have 7a cams. This means that I have atleast as much hp/torque as a CQ off boost with about 500 pounds less weight.

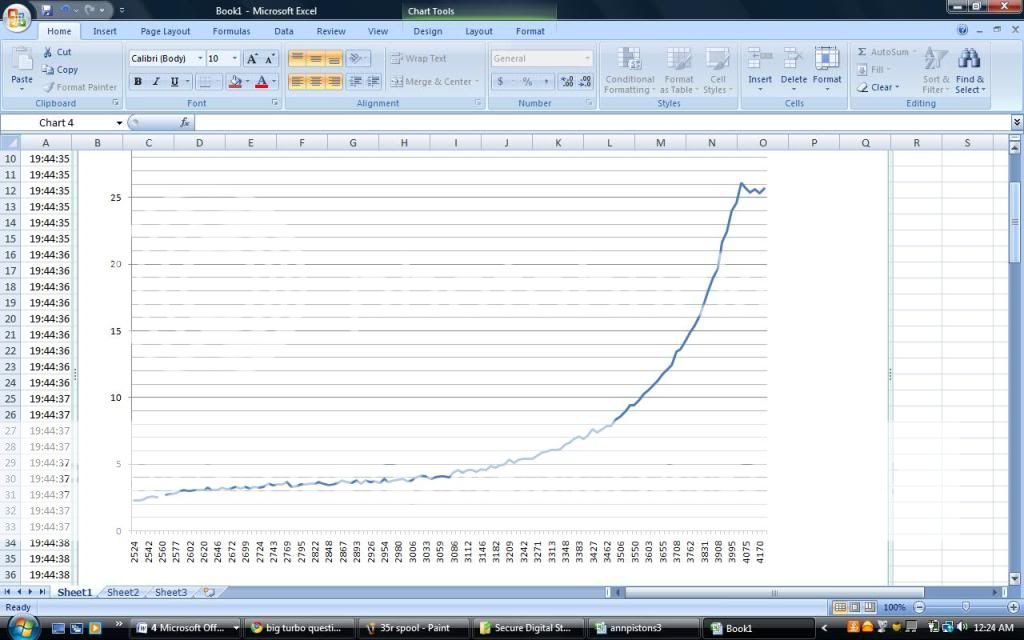

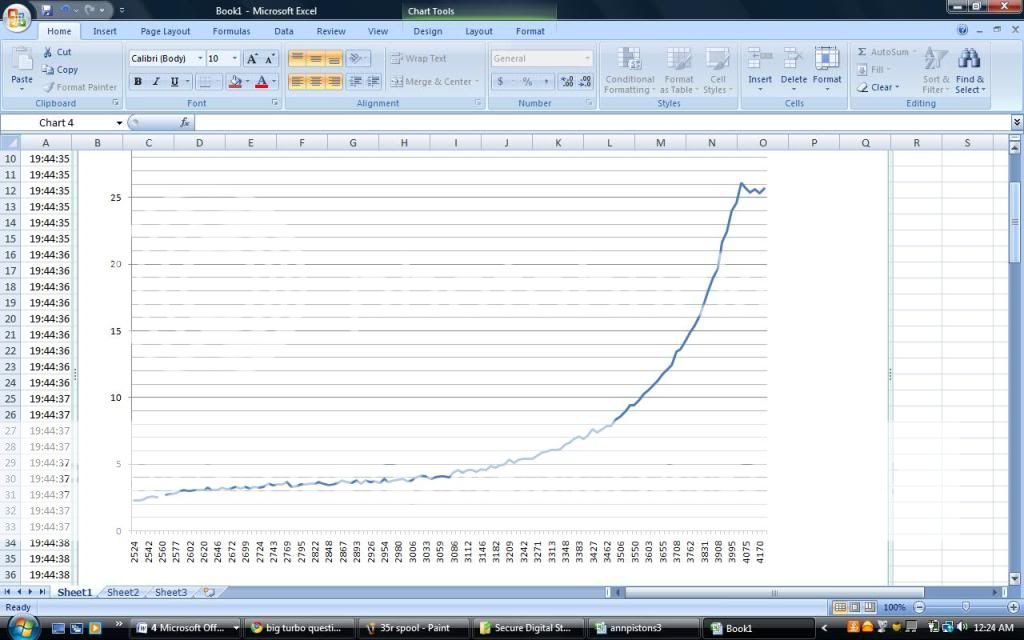

Here is a boost profile of what I have going on now in 3rd gear. I want all the big turbo haters to take a gander at where stock URQ levels(9psi?) happen with the k26. If I capped this turbo at 9psi, we would have close to the same spool. I would love to see the boost profile of a rs2 turbo, as I think this 62mm hta35r spools faster.

Anyway, it is late, and it looks like my baby has finally fallen asleep in the swing at the ripe hour of 1am. Dave is organizing a local dyno day on a new mustang dyno in town. It reads a tad low at 230whp for a stock STI, compared to the normal 250whp I see across the internet, but I hope to still put down 500whp next saturday. I am out of fuel on this 1000cc injectors at 28psi and .78 lambda. I will probably baseline this trip, and then put on a new IC and bigger injectors over the spring and go back later this year for another session. I want to hit a couple of track days before summer, and for now the car is a kick...

PS. Peter, I swapped 4 heads and a bottom end, AND had a baby faster than your installed your v8. I hope that 265whp is worth it buddy...

pps, Tonight trying to unjam my 1-2 hub, I managed to bump into an r8 going the other way on a main road that dumps onto the freeway. I flipped around, and caught up just in time to catch the yellow behind the r8 jumping on the freeway. We got onto the freeway only to see they had reduced the lanes to 1 due to construction. Finally it opened up, and I merged into the middle lane. The R8 stayed put, and a semi approached us, so I jumped on it a bit to get in front of the r8. Once I got around the semi, I merged back over... The r8 had got the memo at that point, and it came ripping up at full bore. I dumped it into third, at about 65/4200 and let her have it.. it got only to my rear quarter before I started to walk away... I slowed back down and prepared for a humble thumbs up, yell out the window "hey I love your car"... What happened next I was not prepared for. The tinted windows on the Oregon plated r8 rolled down, and a CHICK WAS DRIVING!!!!! LOL! There was a man in the drivers seat, and he said "Nice audi". Parts of me thinks that it is probably his car, but the other side of me wants to believe a chick has an r8 and isn't afraid to mash on it on the freeway... I got off at the next exit already late home from my "trip around the block", and reflected on what just happened.. The girl caught me so off guard, I realized that I rolled down my window, but did not say anything. I probably just stared at her them with a blank stare... What a tool

So does it count as a kill if it is a girl?