Ok, back to the update. So I get the original solid lifter head cleaned up and managed to get the 3 exhaust studs along with the two studs from the water neck drilled out and removed. None of them would would just easy out, but I drilled pretty good centers and retapped them. While I had it off I took it apart and hand lapped the valves in and installed new valve seals.

Aaron do you recognize the homemade valve seal pullers?

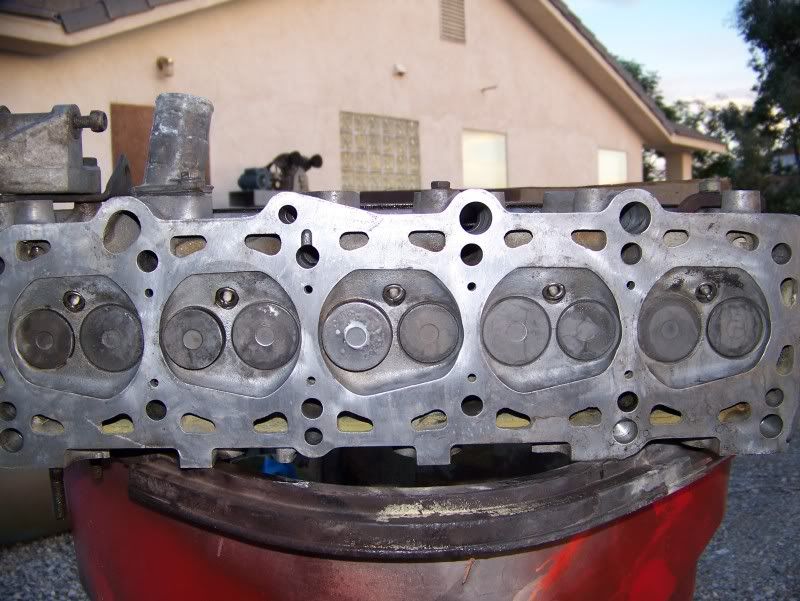

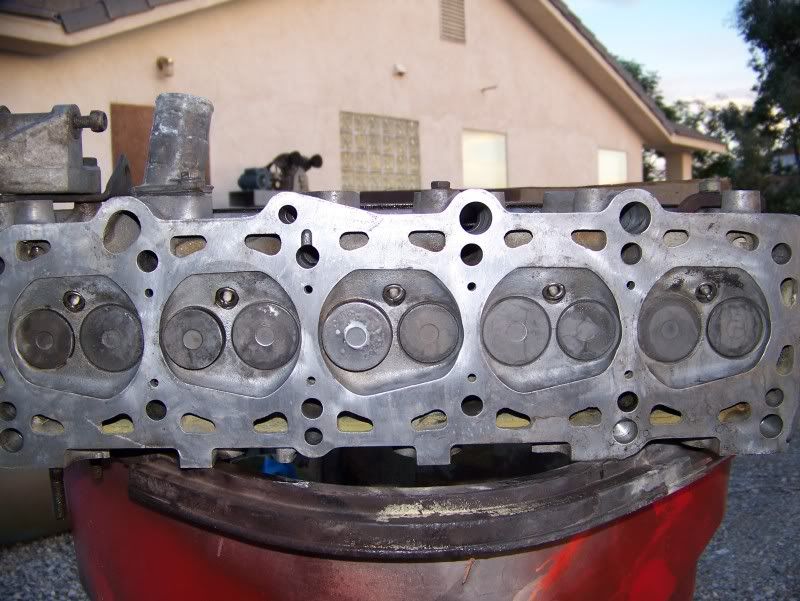

It looked so pretty on the bench. I should have had a seat and valve grind, but time was getting short and I didn't want to go through the reshimming process to set valve lash.

So I'm all excited that the motor is going to be going back together with 2 weeks still left before the GTG. I put the exhaust manifold on while still on the bench with all new studs, washers, and copper nuts. I do final torque on the 1 and 2 cylinder and pull the bottom threads out of both. Now what? I figure that have way too much time in this head to give in now, so I figured that I would weld up the holes, drill, and retap. I really liked the idea of the original head and solid lifters, plus it was in such good shape as far as varnish and wear.

Welded holes

drilled

After the third hole pulled and I didn't get a good fill but had a pocket in the new hole that couldn't be tapped I threw in the towel. These were holes that were pulling threads with new copper coated nuts before they were even getting tight on the manifold. Two of them pulled just getting past the self locking portion of the new nuts.

With a week left I decided I needed to go to plan B last Saturday. I have a hydraulic 20v head that came from His Urq that had a seized bottom end and water in the cylinders. I had originally shied away from it because of being hydraulic and I didn't know if the seat/valves had pitted from the moisture in a wet seized motor. I wish that I would have gone that way to begin with and had the time to go through it. Instead I just rotated the cam so that I could kind of look at the seats for obvious pitting. The kicker is that Sean claims that the head had less than a few thousand miles on it since it was rebuilt. It was out of an early 80s 5ktq so the water ports would match without any problem. I cleaned the runners with a bottle brush and brake cleaner and called it good.

Cleaning plan B head

I'm not sure what the injector shrouds came out of, but they were not WX or MC. They were long shrouds, but an MC injector wouldn't fit into them and they didn't have provisions for the lower o-ring. They looked like they would work so in they stayed especially since the hole size was different than the WX and I wouldn't be able to use the short WX shrouds.

After I installed the head and had the ARPs torqued to 75lbs, I decided that it was time to change out the motor mount that could still easily be reached. It was completely torn apart and had to have two wrenches, one holding the bottom from turning the the other cranking on the nut. When it was out it wasn't good for anything except apparently a lookout post.

The logical step at this time would be to start putting the turbo, intake and CIS back together, but I had the problem of not knowing where I put the oil filter housing nut so I wouldn't lose it. I looked for ever and finely decided to change out the other motor mount so I would have two new ones that sat the same height.

New on the left old on the right.

What a pain to get to the driver's side mount. I finely got enough articulation and leverage to break it loose, only to find that it was the pressed in stud that had broken loose instead of the nut. I'm beginning to think at this point that this car wasn't supposed to go to the GTG, after all my wife says that if I give it to her she will sell it. I thought maybe I could weld two welding rods together to get enough length to reach down to the mount and tack the top side, but decided that I needed to go back to doing something about the oil filter housing nut. After looking one last time it was decided that I would have to steal the one off of my spare motor that came in the good looking blue van. Of course the PO hadn't drained the oil before removal so I was stuck with a motor on a palet with no way to get to the plug other than a hoist. How much of a mess could 5 quarts of oil really be? I decided enough to warrant a catch basin which I had hidden under the coupe gt so as not to look so messy to the wife. (it probably didn't help) I go out to drain it into a container so that I would have plenty of room and this is what I find.

I didn't know whether to be hot or happy, but decided to move full forward on getting the turbo, intake and that side of the motor put back together and leave the motor mount for a better time.

Work is calling so I'll post up the rest of the saga at a different time.