Page 13 of 17

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Sun Dec 08, 2013 6:45 pm

by my2000apb

MORE!!

I got the front cross member supports finish welded.

- front x member bracing finished.jpg (1.4 MiB) Viewed 42752 times

- front x member bracing finished2.jpg (1.12 MiB) Viewed 42752 times

- front x member bracing finished3.jpg (1.3 MiB) Viewed 42752 times

As well as the 20/24AN radiator inlet/outlets, finish welded in all their glory. Very smooth transitions on the inside of these pieces. Now that the radiator is fully mounted I can make the inlet/out fit for great routing of coolant hoses.

- radiator inlet outet 20-24 an welded.jpg (1.46 MiB) Viewed 42752 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Sun Dec 08, 2013 6:50 pm

by my2000apb

I also got a chance to seam seal up the rear inner strut towers.

Now I just need to do the inner wheel wells in the back. It looks soooo much cleaner using grey not the white seen here. Its getting a touch of primer asap

- rear inner strut towers sealed.jpg (1.42 MiB) Viewed 42752 times

- rear inner strut towers sealed2.jpg (1.29 MiB) Viewed 42752 times

- rear inner strut towers sealed3.jpg (1.33 MiB) Viewed 42752 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Sun Dec 08, 2013 6:54 pm

by my2000apb

UPDATE!!!

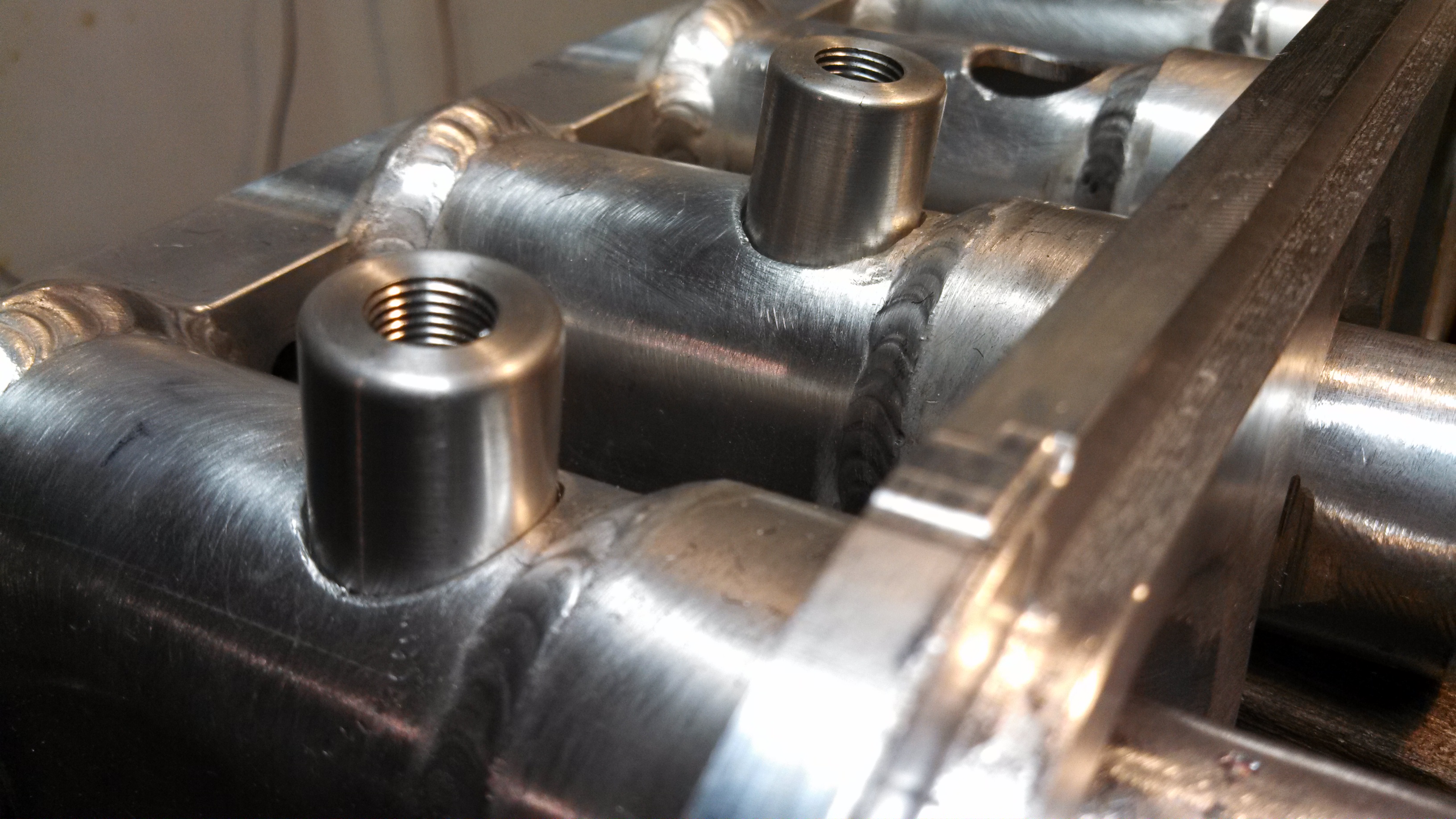

I drew up some water/methanol nozzle bungs and had them machined up by a friend. They are 1/8”-27 NPT. The inner end radius exactly matches the inner end radius of the Ross Machine oval tubing.

- water methanol bungs machined.jpg (1.77 MiB) Viewed 42752 times

- water methanol bungs machined2.jpg (1.85 MiB) Viewed 42752 times

- water methanol bungs machined3.jpg (1.09 MiB) Viewed 42752 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Sun Dec 08, 2013 7:03 pm

by my2000apb

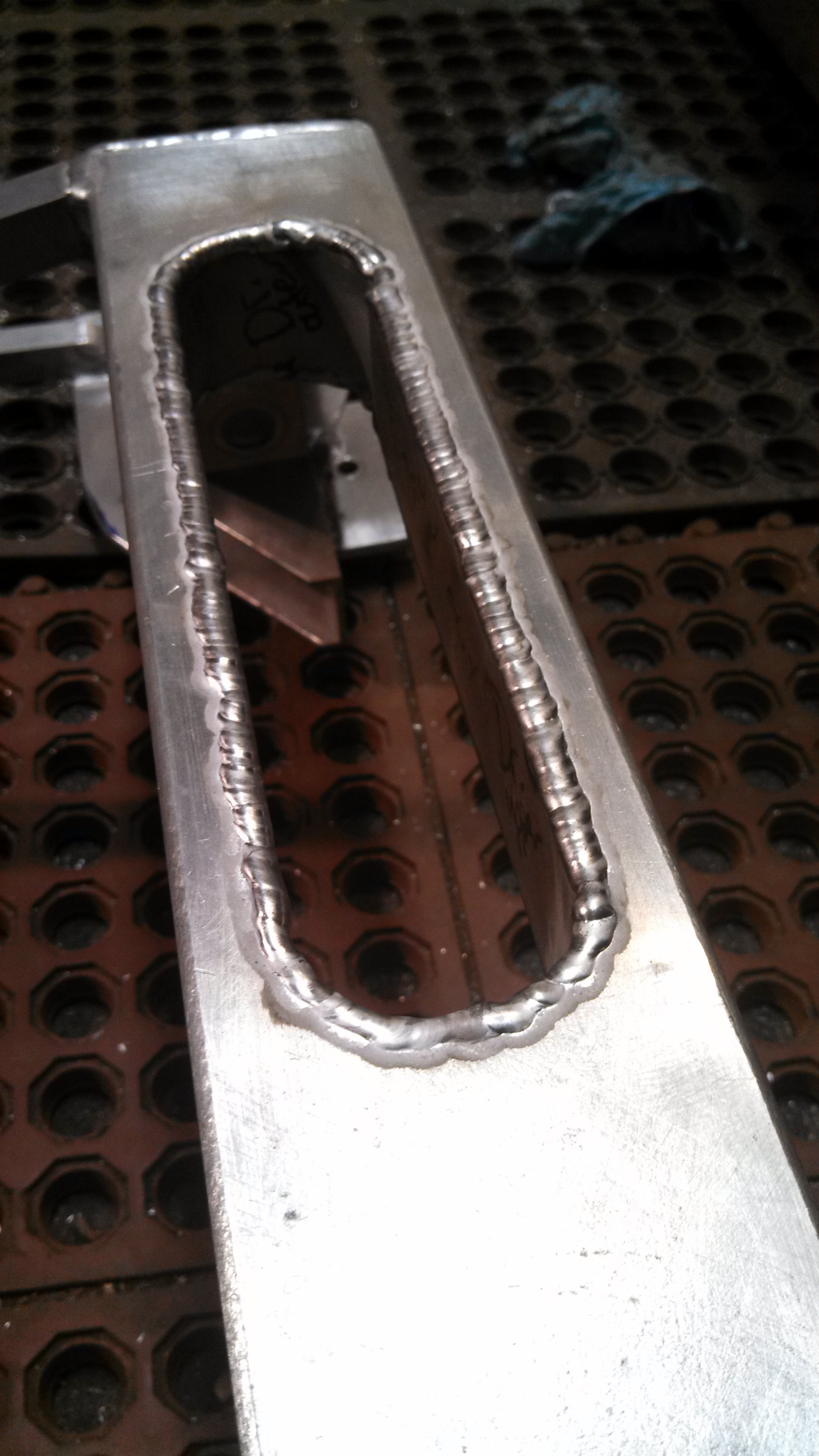

More. I got the intake manifold runners all drilled and prepped for bung welding.

- water methanol IM holes for bungs.jpg (1.28 MiB) Viewed 42752 times

- water methanol bungs ready to weld.jpg (1.55 MiB) Viewed 42752 times

I used a piece of solid stock 1.25” the put down in the runner so the bung will sit evenly and flush in the runner when its finish welded. It just needs final texture/smoothing before the plenum is welded on. See pic

- water meth bungs- in-runner radius detail.jpg (1.95 MiB) Viewed 42752 times

And here they are all welded on.

- water methanol bungs finish welded.jpg (1.92 MiB) Viewed 42752 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Sun Dec 08, 2013 8:10 pm

by DE80q

Woot! looking good!

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Mon Jan 13, 2014 3:38 pm

by my2000apb

UPDATE!!!

Ok lets get caught up!

I got a lot of time over the Christmas/ new year holiday period to work on the car.

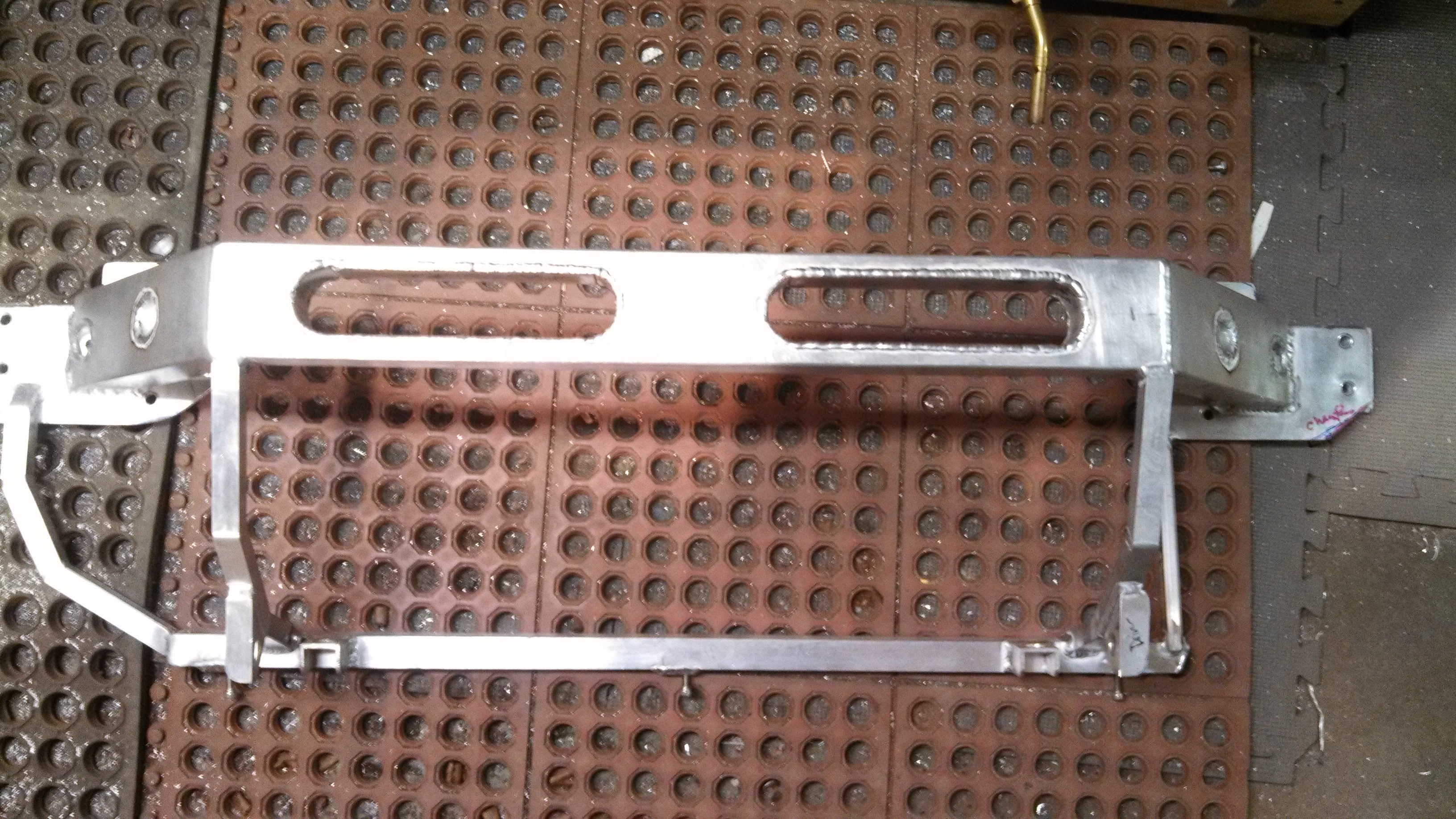

I used a hole saw and some carbide action to make some IC breathing holes in my front x-member. There’s no use having a massive intercooler if its not all getting air, so now it is!!

The holes will be flappered down and smoothed.

Here they are prepped to weld

- IC fresh air holes prepped2.jpg (1.37 MiB) Viewed 42700 times

Here they are all welded up.

- IC fresh air holes welded.jpg (1.27 MiB) Viewed 42700 times

- IC fresh air holes welded2.jpg (1.61 MiB) Viewed 42700 times

- IC mount fresh air holes welded3.jpg (1.65 MiB) Viewed 42700 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Mon Jan 13, 2014 3:41 pm

by my2000apb

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Mon Jan 13, 2014 3:43 pm

by my2000apb

MORE!!

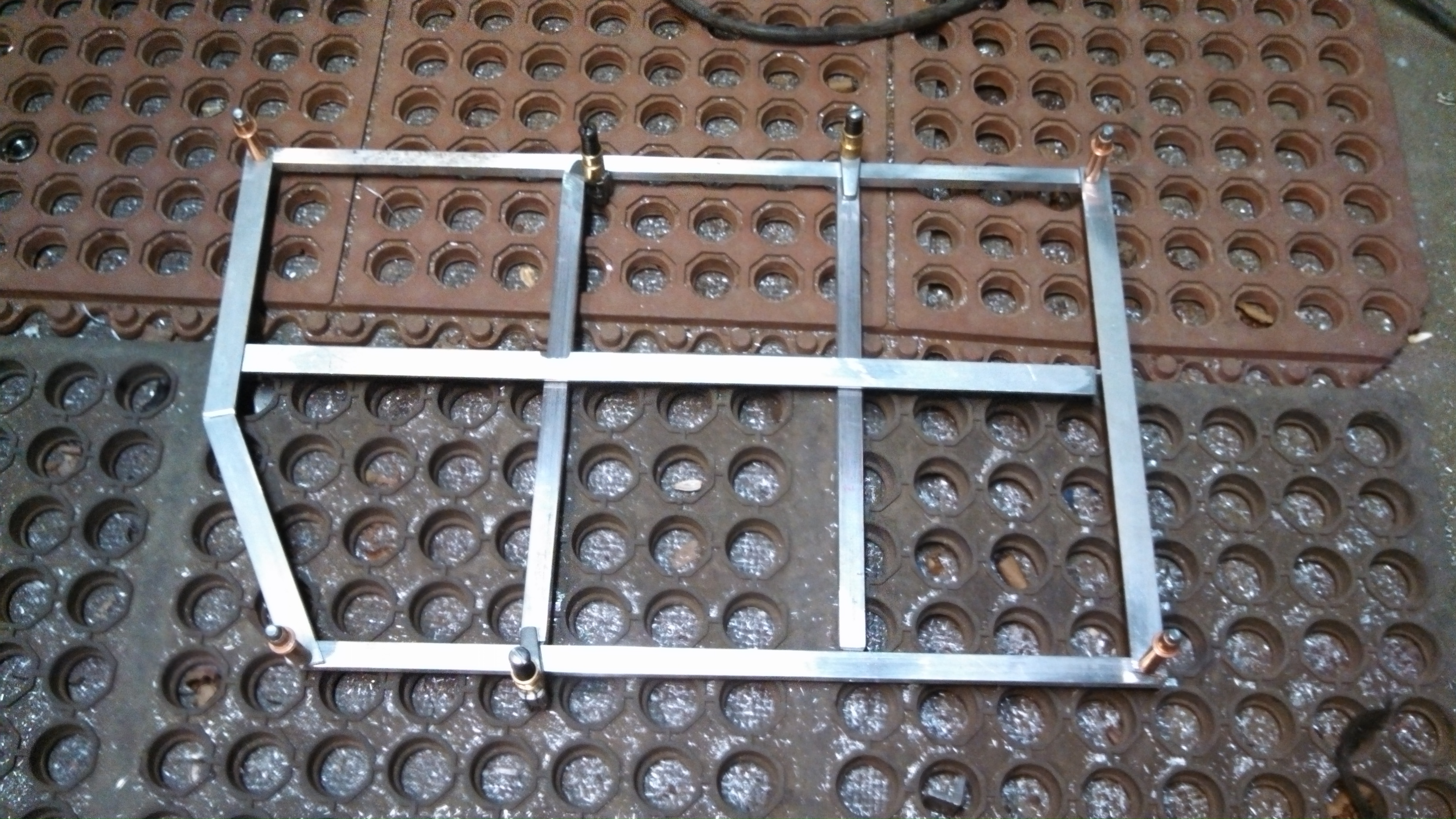

With the driver and passenger seats moved quite rearward, I needed to make a passenger side footrest. There will also be a small, false-floor built in for a heel rest.

Here it is framed out.

- passenger footrest frame.jpg (1.95 MiB) Viewed 42699 times

Note the jigsaw construction.

- passenger footrest frame jigsaw.jpg (1.42 MiB) Viewed 42699 times

- passenger footrest frame jigsaw2.jpg (1.36 MiB) Viewed 42699 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Mon Jan 13, 2014 3:45 pm

by my2000apb

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Mon Jan 13, 2014 3:59 pm

by my2000apb

UPDATE!!!

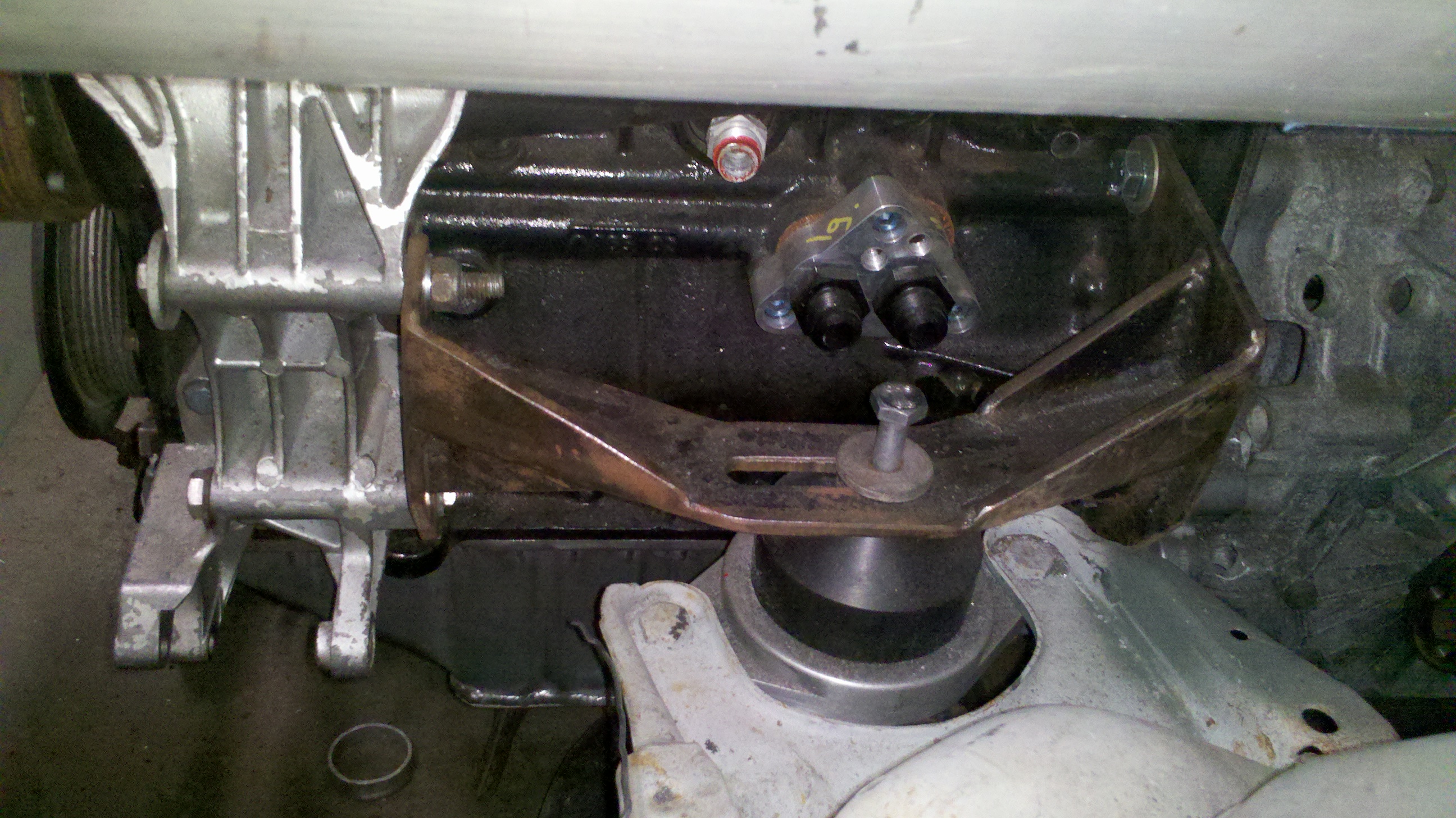

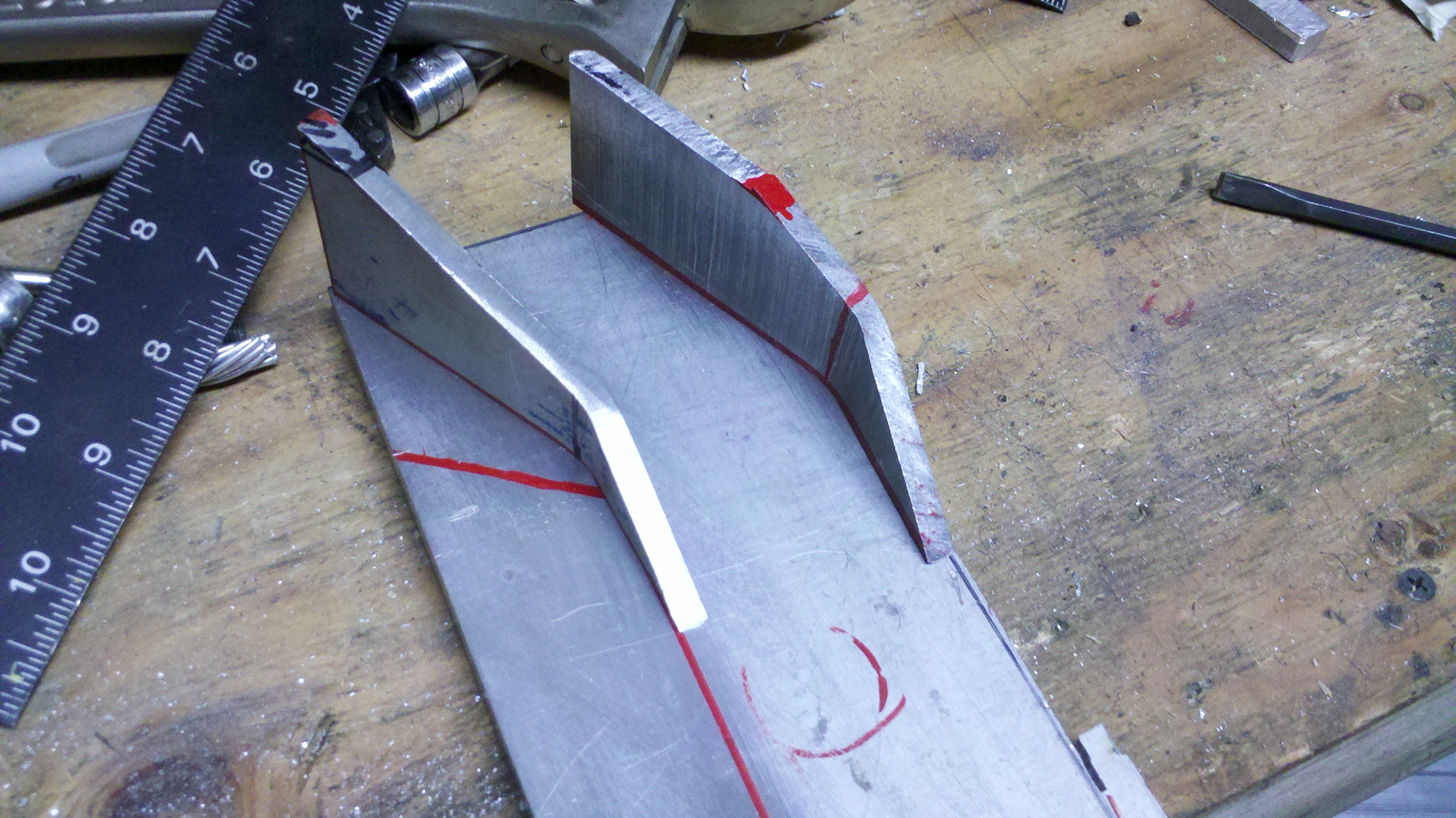

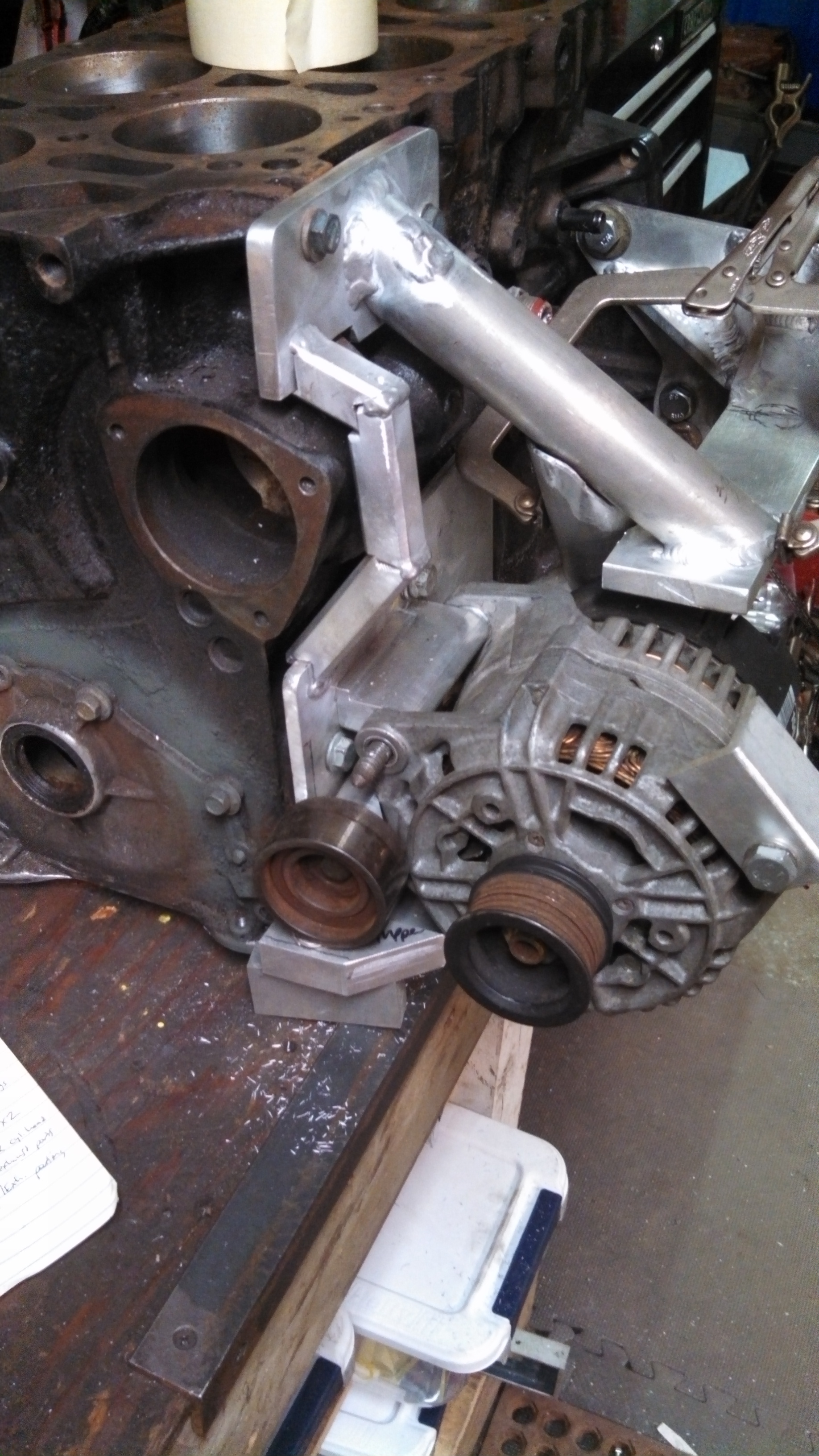

I finally tore back into the re-doing of the driver’s side engine mount arm. There was nothing really “wrong” with the first version, but it was made to be replaced haaha and utilized the oem accessory bracket. I have no use for this oem bracket, as im only running an alternator and we cut off the ALT mount to fit the intake manifold haha, so ground up remodel had to happen

- engine mount soon to be redone.jpg (1.32 MiB) Viewed 42697 times

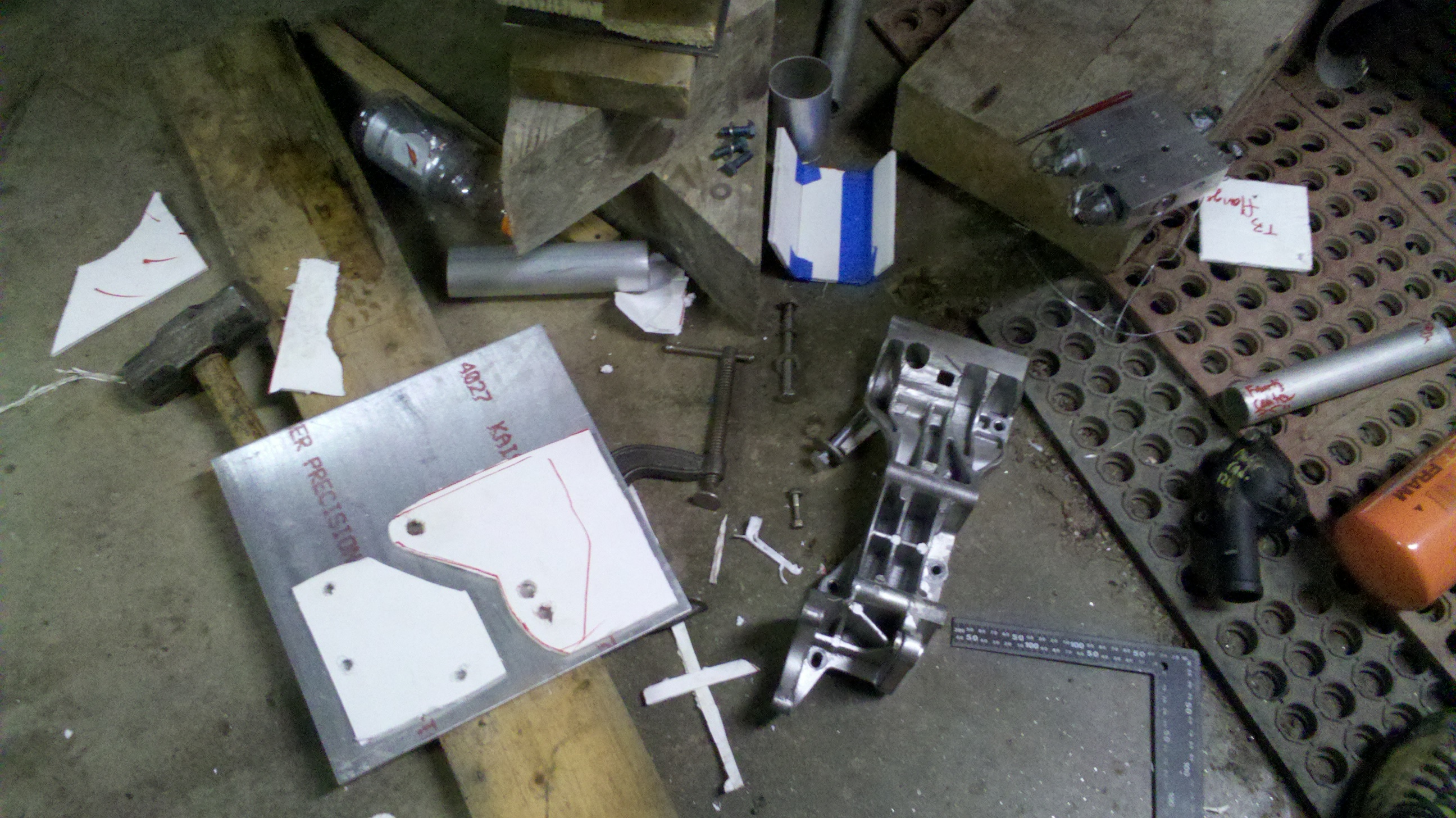

Templates being made

- engine mount arm remake in alu templates.jpg (1.24 MiB) Viewed 42697 times

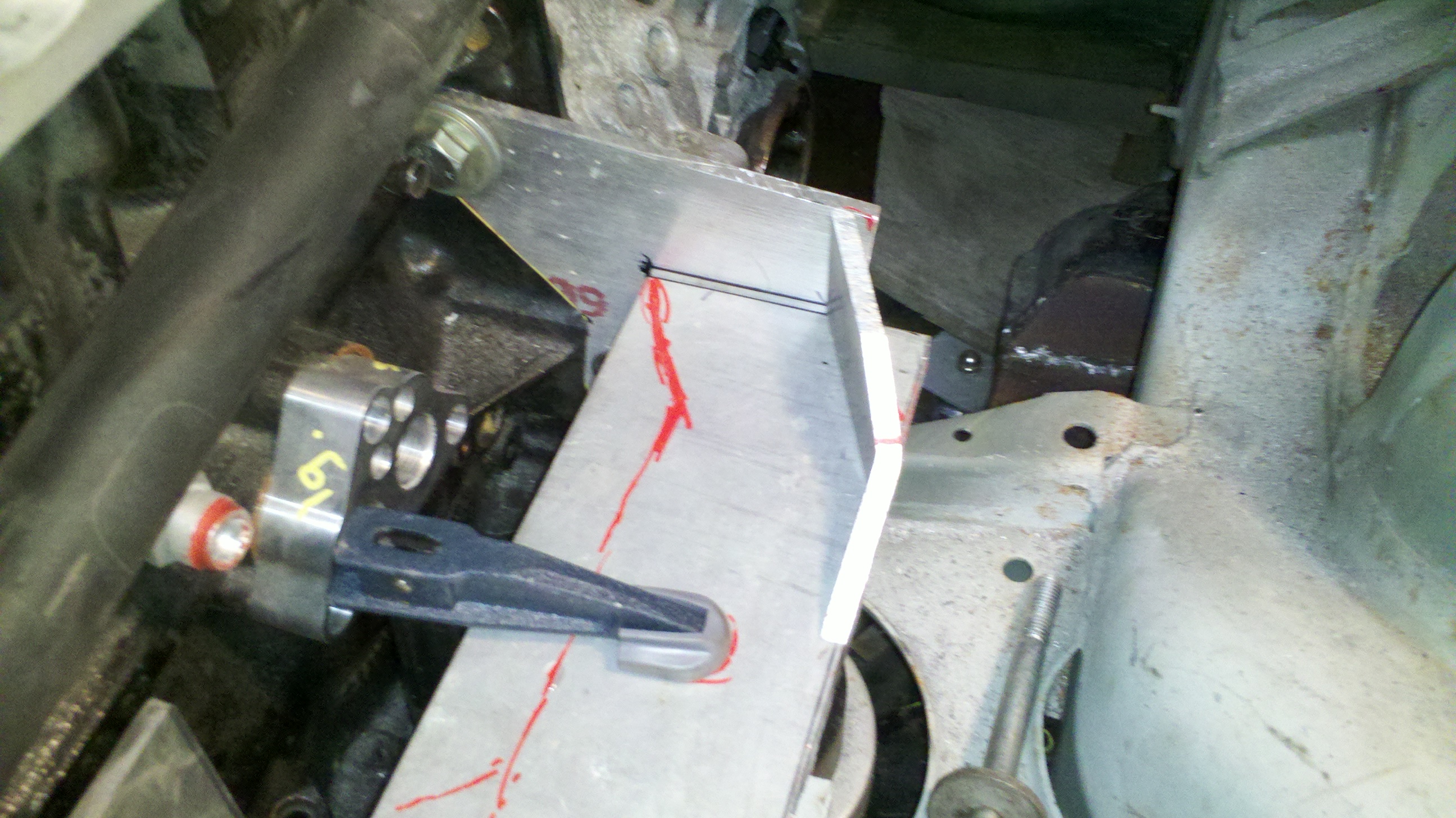

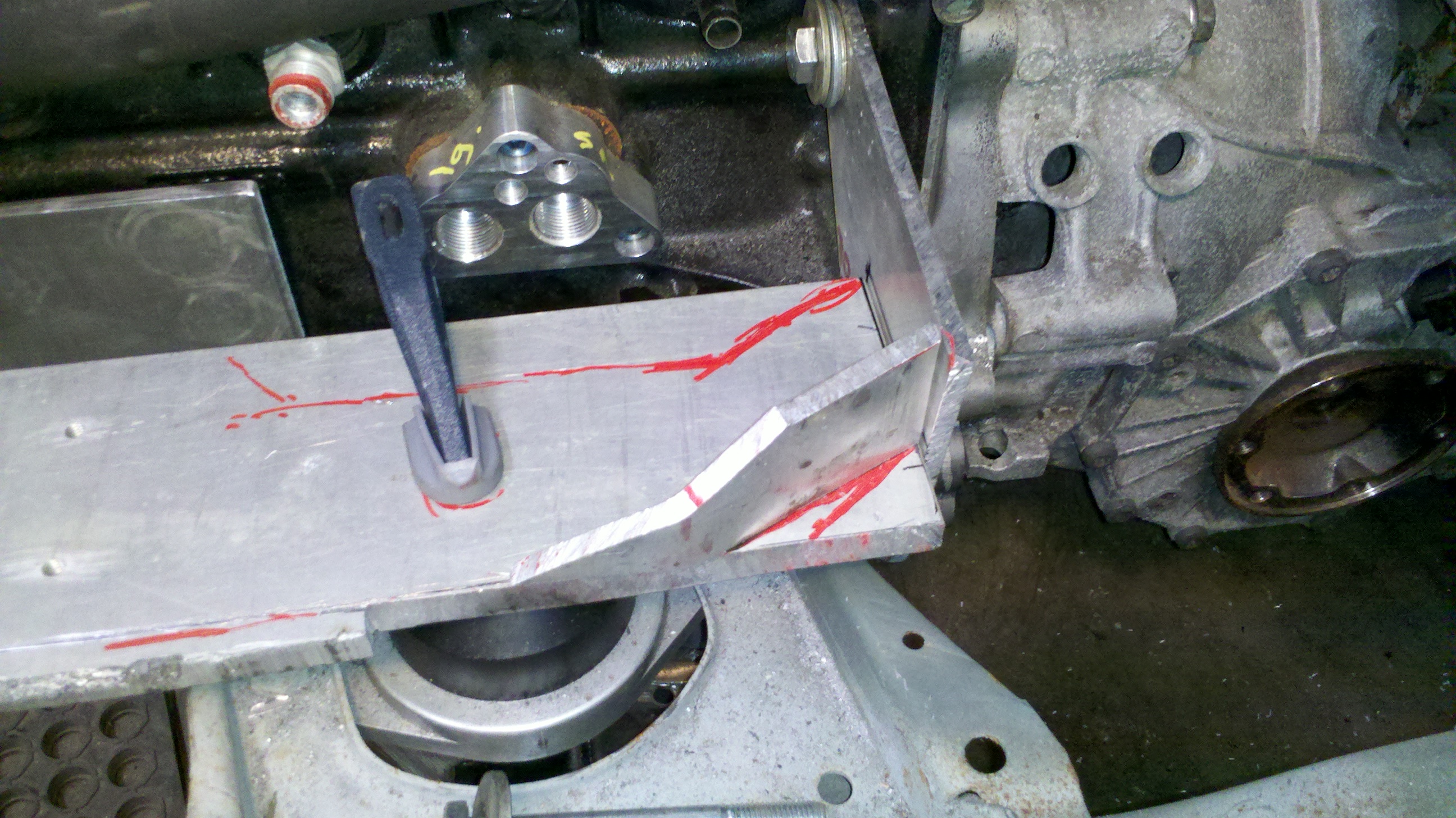

Ready for some welding.

- engine mount arm coming together.jpg (1.13 MiB) Viewed 42697 times

- engine mount arm coming together2.jpg (1.26 MiB) Viewed 42697 times

- engine mount arm coming together3.jpg (1.35 MiB) Viewed 42697 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Mon Jan 13, 2014 4:00 pm

by my2000apb

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Mon Jan 13, 2014 4:09 pm

by my2000apb

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Mon Jan 13, 2014 4:11 pm

by my2000apb

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Mon Jan 13, 2014 4:26 pm

by my2000apb

MORE!!

Upper mount arm plug weld is done!

- plug weld, upper done.jpg (1.83 MiB) Viewed 42697 times

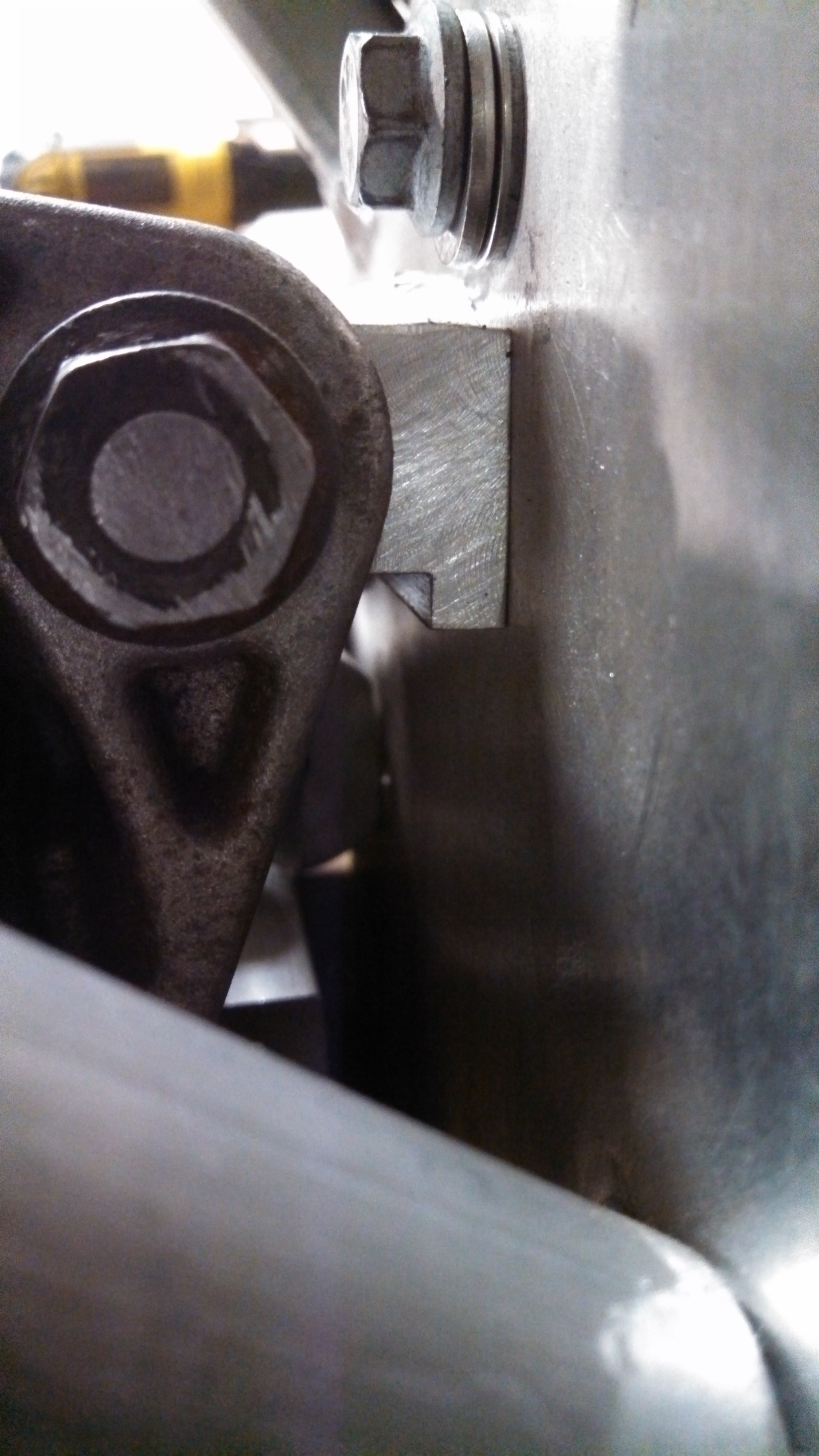

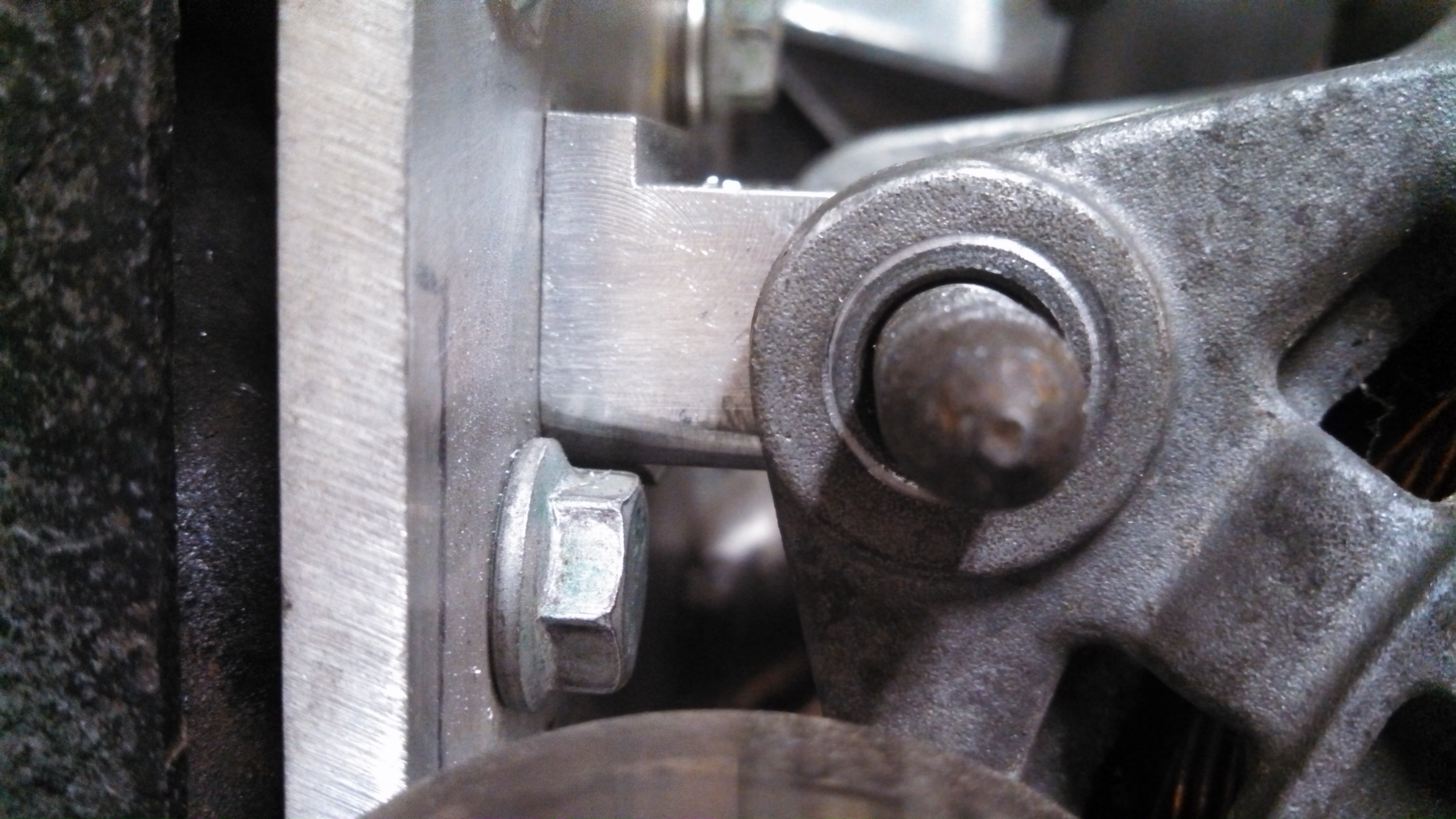

I got my machined bits back from ryan, the idler mount and alternator through bolt mount are done and ready for install.

- ALT bracket from above.jpg (1.39 MiB) Viewed 42697 times

The alt. mount piece is cut from a large T shaped piece of stock, so we can put the through bolt as close or far from the block as we want as well as use the “T” legs to give it a larger/stronger footprint on the lower mount plate.

And through bolt clearances front and rearward

- Alt bracket bolt relief from rear.jpg (1.19 MiB) Viewed 42697 times

- ALT bracket bolt relief from front.jpg (1.42 MiB) Viewed 42697 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Mon Jan 13, 2014 4:28 pm

by my2000apb

MORE!!

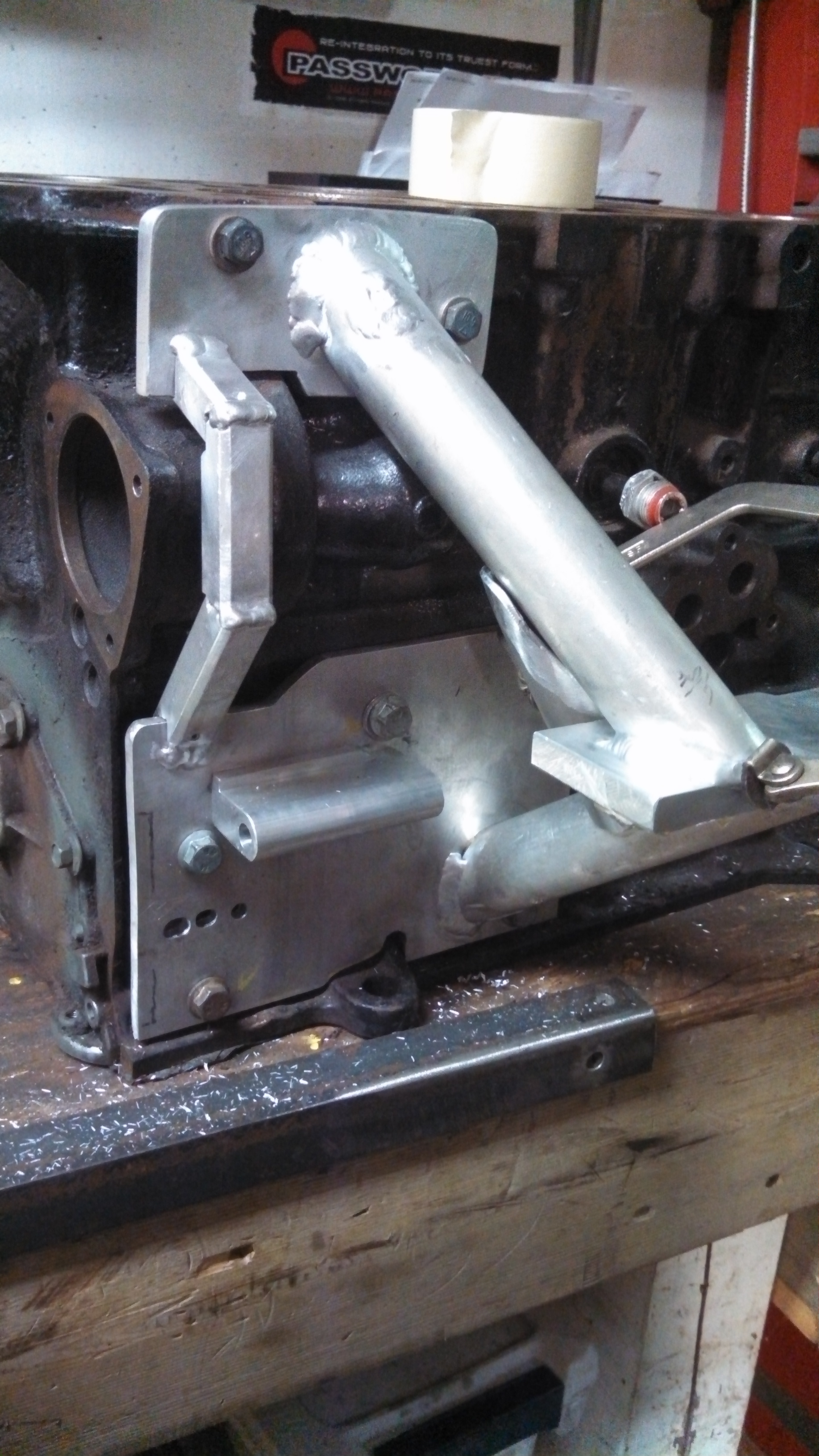

All the pieces are ready for final welding.

The alt mount and tensioner mount are both drilled and tapped and mounted to the bac of the plate with m6x1mm bolts. They are very hand tight haha, so I can align them, but still tight enough that they don’t move if I let go of them.

- ALT mount and tesnioner installed.jpg (1.4 MiB) Viewed 42711 times

- ALT and tensioner installed.jpg (1.52 MiB) Viewed 42711 times

Haydn hooked it up bigtime!!! He let me borrow his Dayco accessory belt laser alignment tools!!!!!!!! These things are sweeeet. One is curved and relieved to sit in the serp pulley grooves, and has a laser line that goes across the other pullies. We got them spot on!!! Thanks again

And some pics!

- dayco pulley alignment tool.jpg (1.37 MiB) Viewed 42711 times

- dayco pulley alignment tool2.jpg (1.06 MiB) Viewed 42711 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Thu Jan 30, 2014 9:49 am

by my2000apb

UPDATE!!!!!!!!!

Ok once again let’s get caught back up to the work that has been completed.

As per requested by others hahah

death 4kqt wrote:header porn is the best

timmmy wrote:MORE.... lets get to the good stuff already

Ok, ok, I got it hahahaha

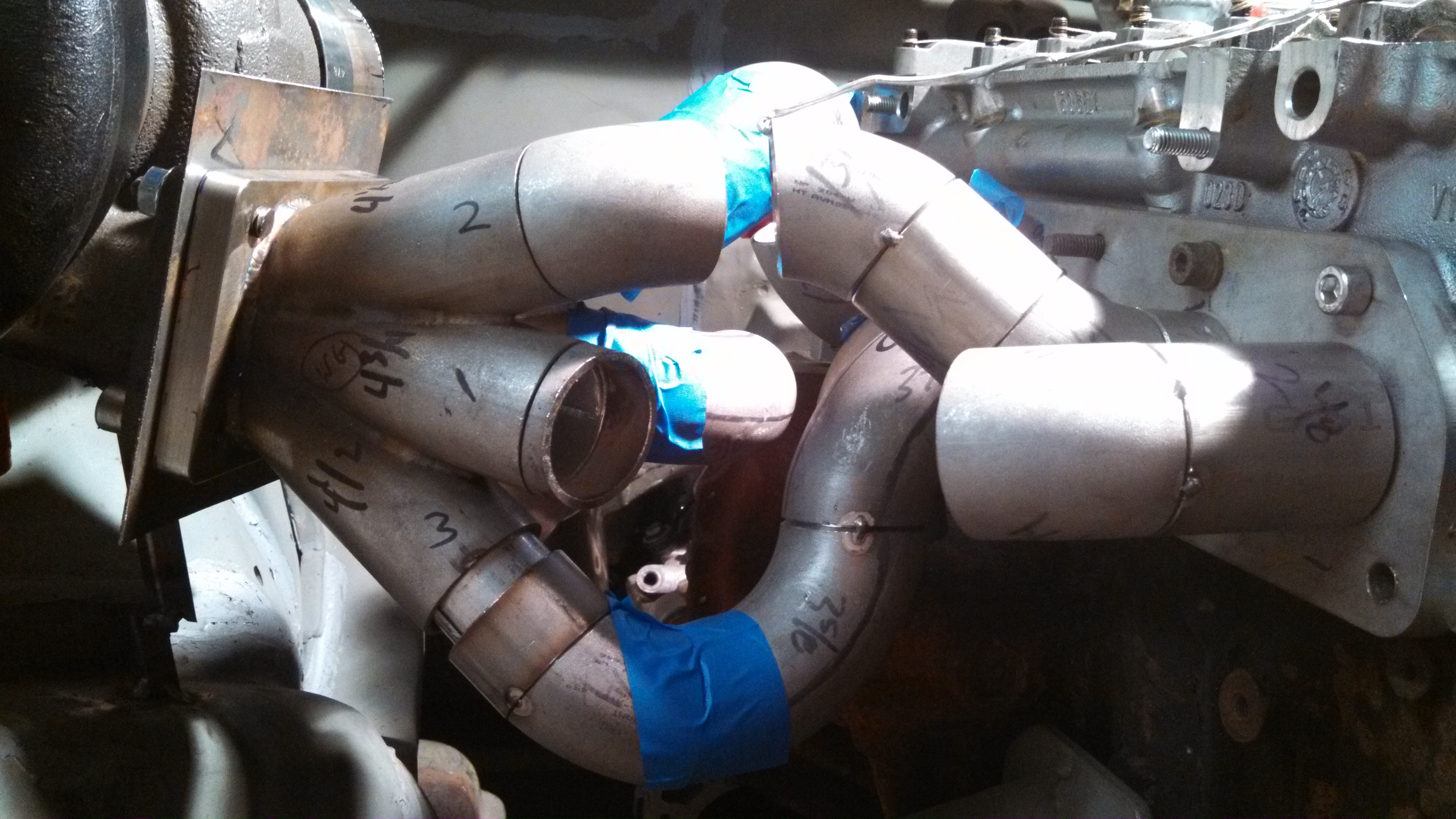

Well here she is!!!

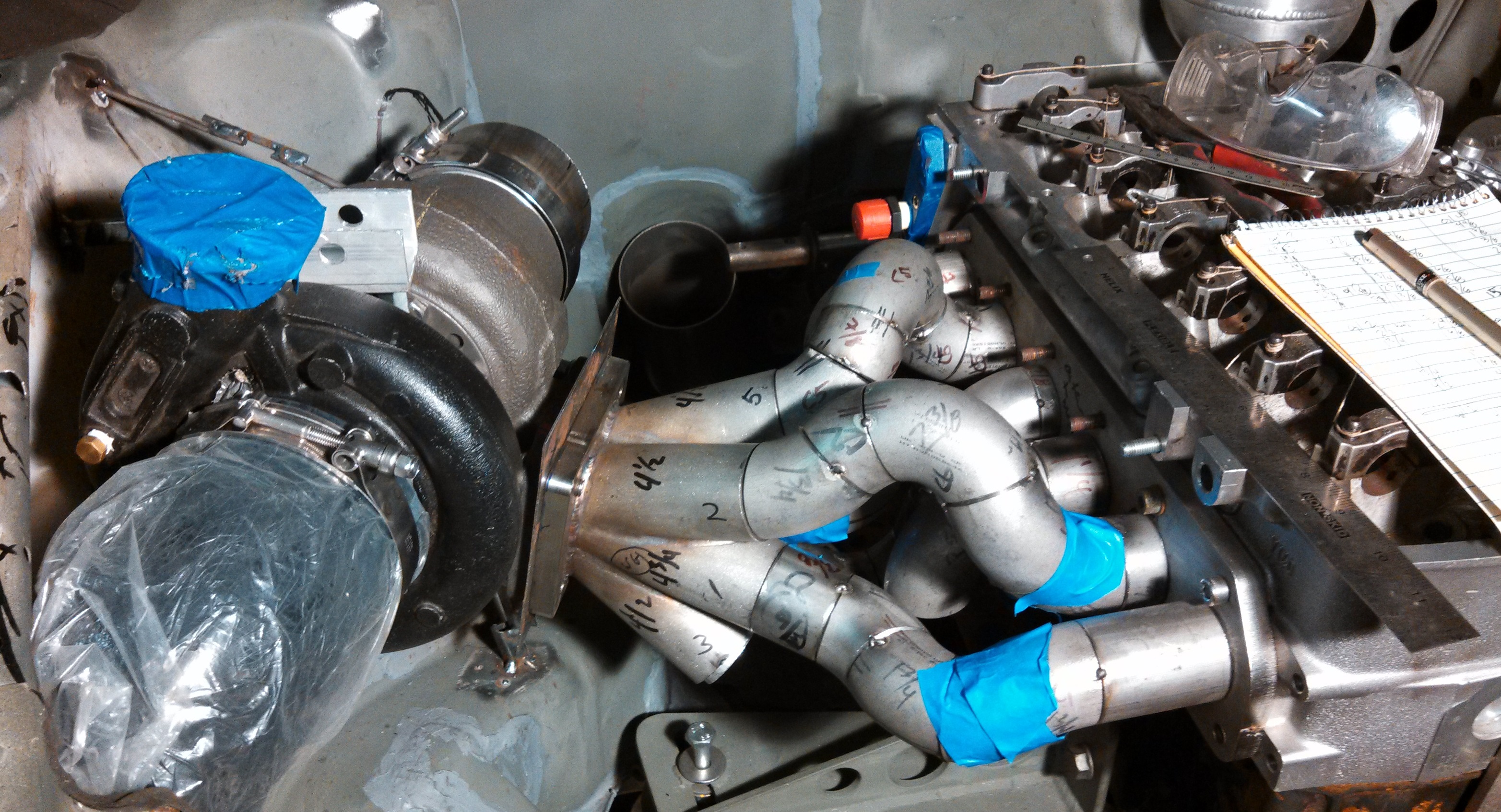

I’ve had the manifold collector seam welded in and out for a while now, and now that I have a ton of weld-els, it’s time to dig right in and get to building.

The collector has been seam welded inside and out, completely. And with that mostly polished up, its runner time!

Based on the vr6 firing order, the front three cylinders and the rear three get paired together for the divided manifold. This saves me a lot of headache in regards to making the runners equal length.

So, I made all the runners, mostly based on smooth flow. The center line lengths have been calc’d from the centerline radius numbers that Vibrant provides.

ROUND 1 pictures

- EM rd1 getting started.jpg (1.98 MiB) Viewed 42622 times

- EM rd1 adding pieces.jpg (1.48 MiB) Viewed 42622 times

- EM rd1 getting there.jpg (1.85 MiB) Viewed 42622 times

- EM rd1 getting there addl angle.jpg (1.67 MiB) Viewed 42622 times

the 3,4,5 runners are all right around mid 14”, the 1,2 and 6 runners were about 15 ½”, 16” and almost 17” respectively. That was not going to work for me so I cut half the manifold back up. It looked all cool first go around, but cutting it up, while dishearteneing is something that needs to be done to make it better hahahaa.

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Thu Jan 30, 2014 9:50 am

by my2000apb

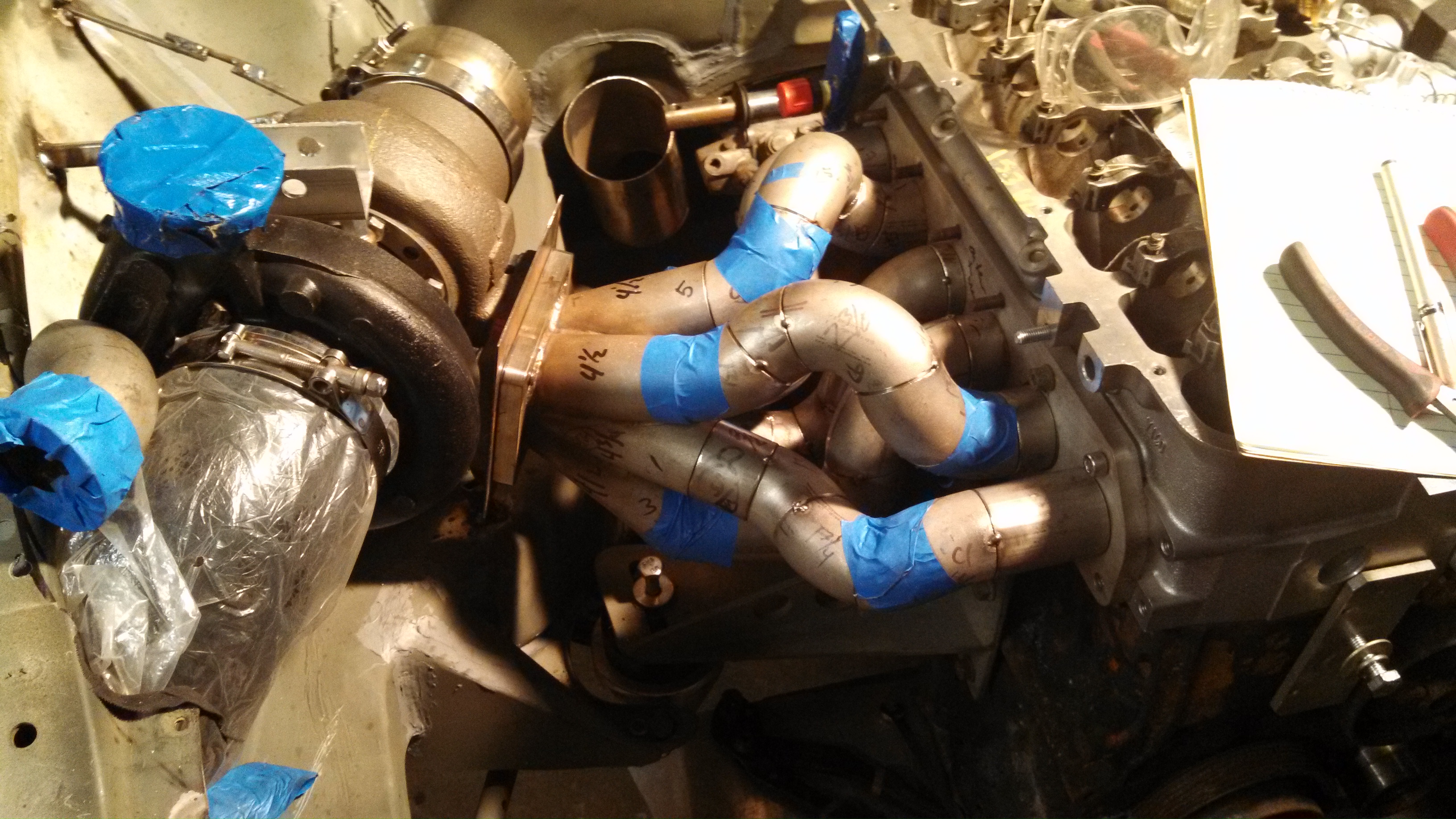

MORE!! So I cut a few of the runners off and set to making them shorter. I want all the runner lengths to be a close in length as possible. So I changed them around and set to re-calc’ing the center line lengths. Closer but not close enough, they are now within about 1.5” of each other, not good enough. So I cut it back apart!

ROUND 2 pics!!

And here she is in all her glory!!!!!!!!!!

So its tacked together, awaiting finish seaming and backpurging at Higbee Fab.

- EM rd2 above.jpg (1.81 MiB) Viewed 42622 times

- EM rd2 above2.jpg (1.54 MiB) Viewed 42622 times

- EM rd2 jsut gotta do #3.jpg (1.62 MiB) Viewed 42622 times

- EM finish tacked!!!.jpg (1.91 MiB) Viewed 42622 times

- EM finish tacked above.jpg (1.88 MiB) Viewed 42622 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Thu Jan 30, 2014 9:52 am

by my2000apb

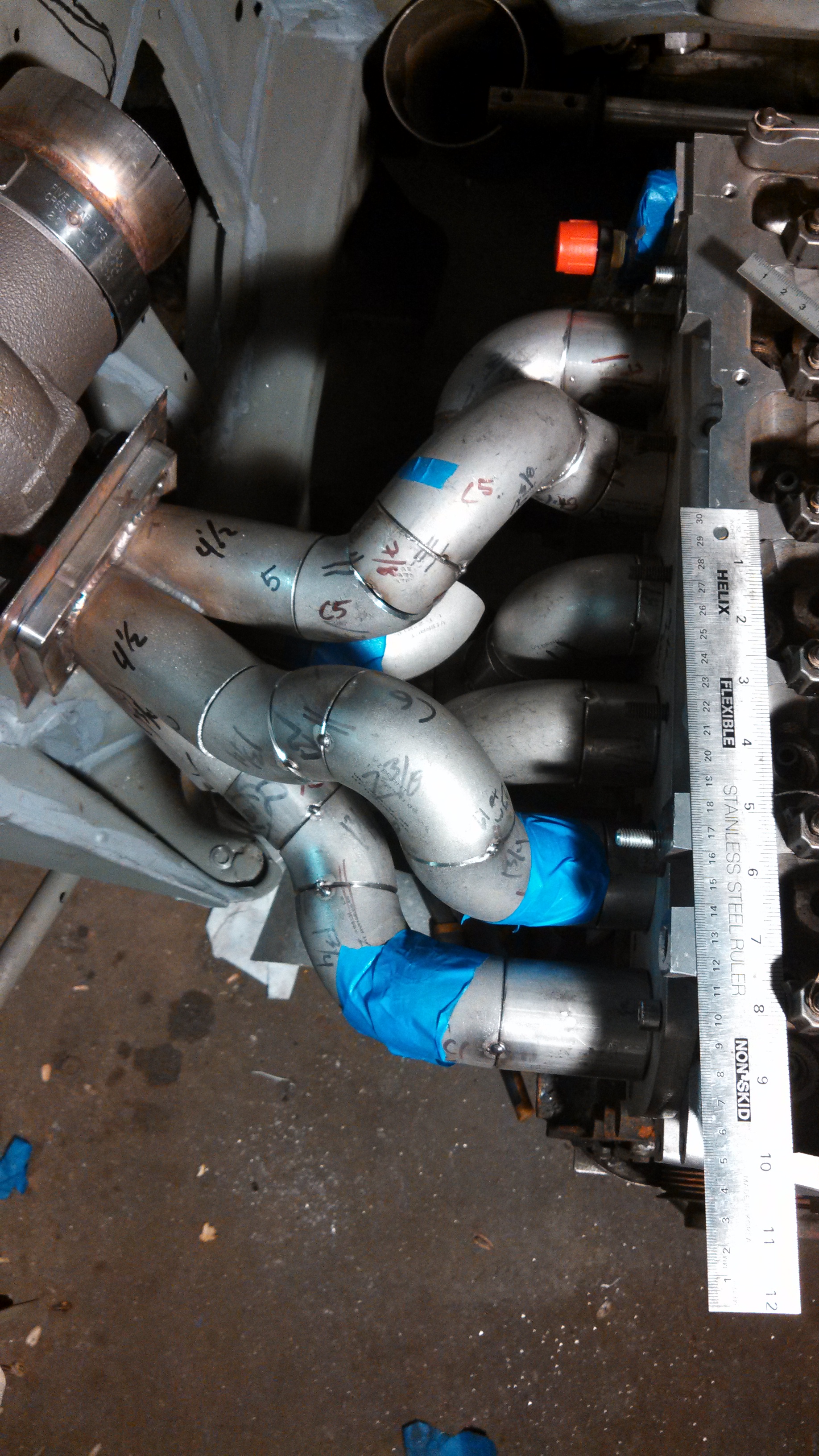

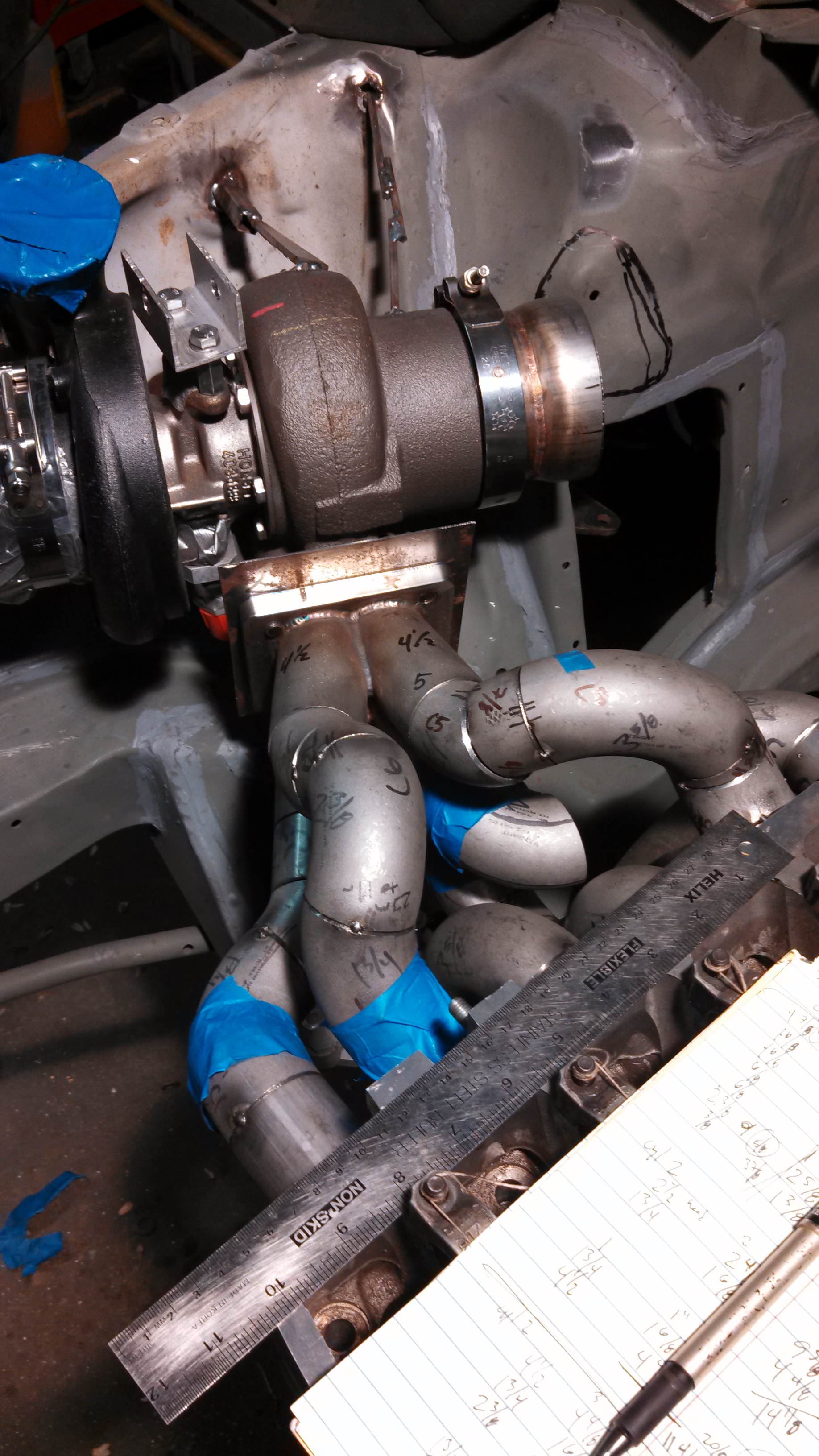

UPDATE!!!

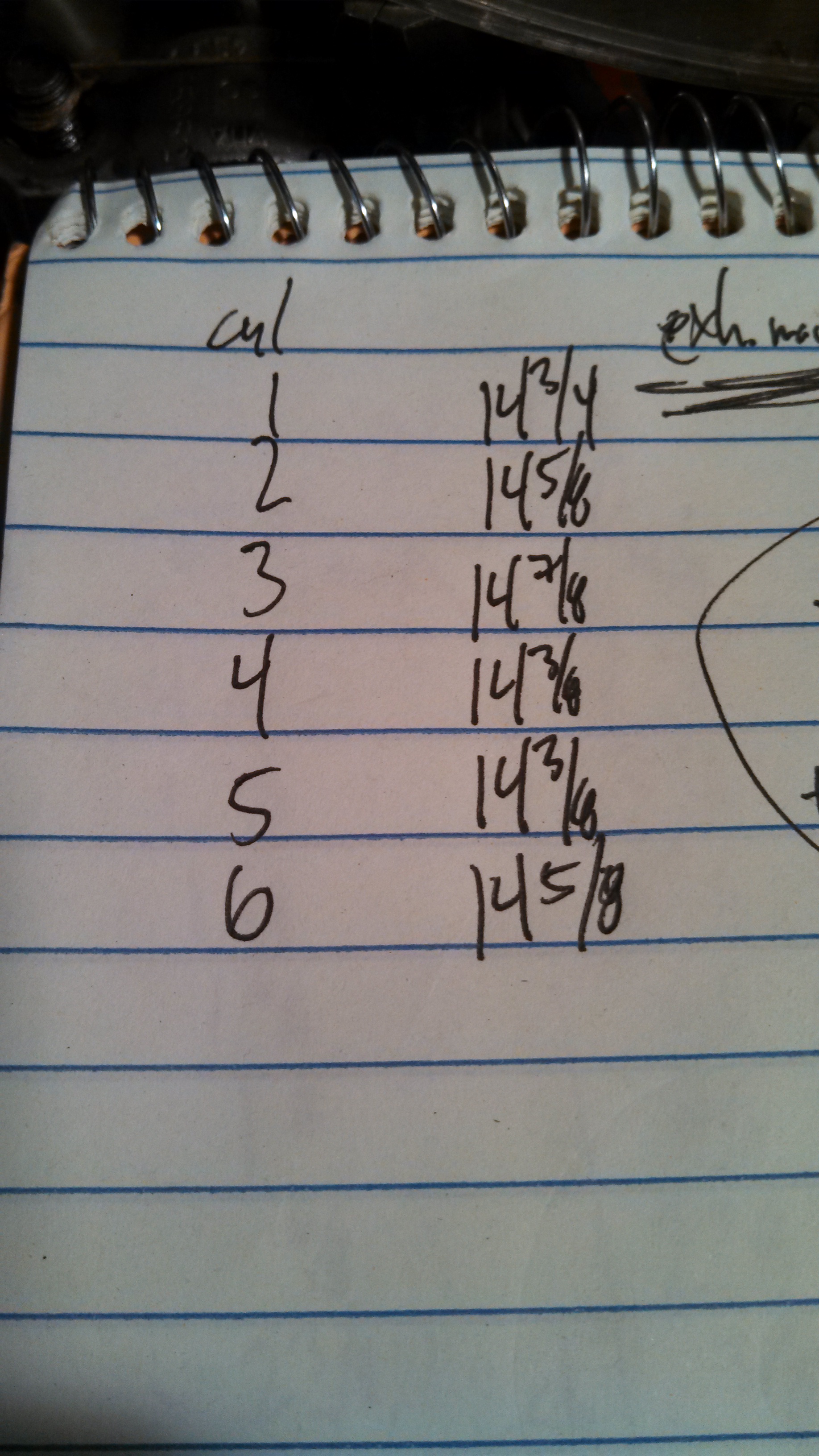

With a target runner length of 14 5/8 inches, we came pretty damn close.

The runners are with ¼” deviation from target length, that’s pretty damn close!

- manifold kit lol.jpg (1.54 MiB) Viewed 42622 times

- runner lengths finalized.jpg (1.39 MiB) Viewed 42622 times

And with the runners finalized it was time to start on dual wastegate mounting.

Collector is now drilled for dual Tial MVR 44’s.

PICS!

- EM collector drilled for WG's.jpg (1.17 MiB) Viewed 42622 times

- EM collector drilled for WG's2.jpg (1.35 MiB) Viewed 42622 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Thu Jan 30, 2014 9:56 am

by my2000apb

MORE!!!

Wastegate tubes are tacked on, now I just need to mark them, pop them off, and smooth/grind them to fit as flush as possible inside the collector.

- EM wg tubes tacked.jpg (1.85 MiB) Viewed 42622 times

- EM wg tubes tacked from above.jpg (1.86 MiB) Viewed 42622 times

Wastegate to runner clearances are good, I will most likely be running banjos on the Tial fitting to improve clearances.

- EM - WG clearances.jpg (1.42 MiB) Viewed 42622 times

I had Ryan @Higbee Fab, use the small water cooled torch to weld the inside of the collector where the WG tubes meet the runners. I’ve begun smoothing and polishing it , here’s a few pics, much more to come once its finish polished on the inside.

- EM WG holes welded inside ready for carbide time.jpg (1.68 MiB) Viewed 42622 times

- EM smoothing inner collector post WG tube welding.jpg (1.35 MiB) Viewed 42622 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Thu Jan 30, 2014 10:09 am

by my2000apb

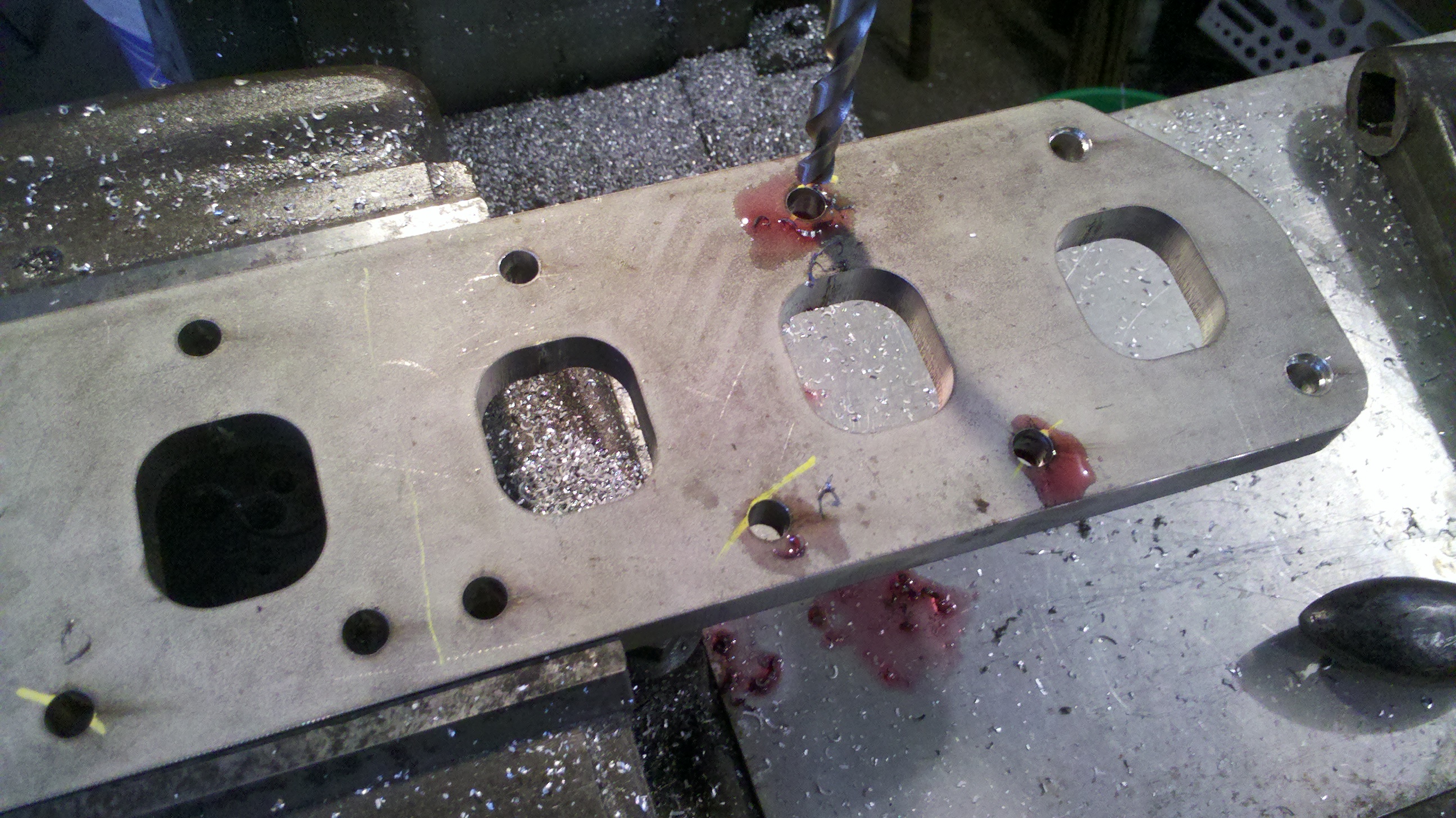

UPDATE!!!

Ok, now a small, out-of-timeline update for some pics I couldn’t find hahaha

- EM getting drilled upclose.jpg (1.34 MiB) Viewed 42622 times

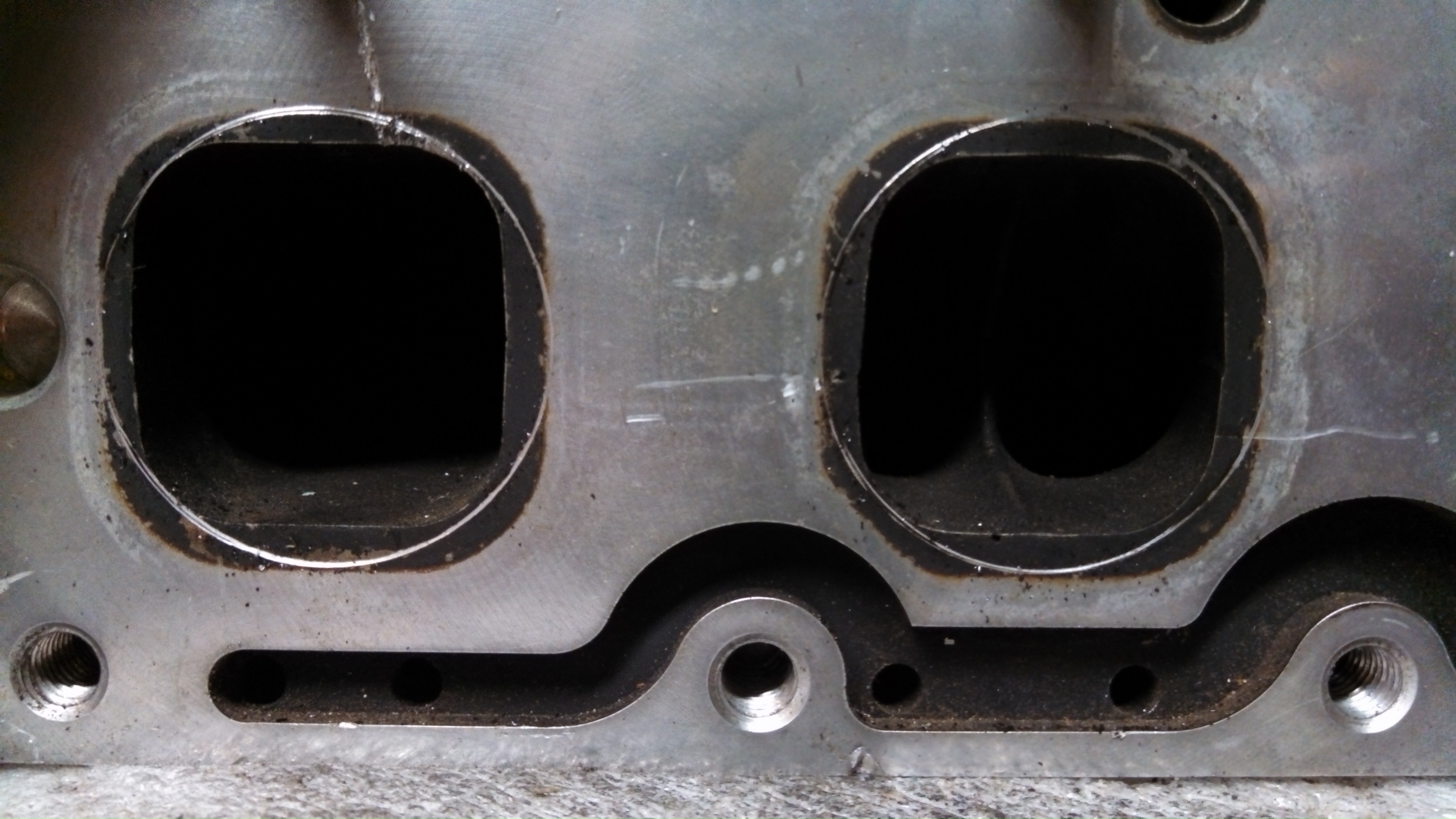

The exhaust ports on the VR are more of a rounded-corner, square and obviously the exhaust manifold runner tubing is round. I started off by carbide-blending the squarish holed flange towards a more round shape. Hahaha that sucks, its going to take forever to do QTY6! Transitions in ½” 304! Ahhaha not going to do it.

- EM port to runner shape transfer.jpg (1.14 MiB) Viewed 42622 times

- EM 1.5 inch runner to rect. comparo.jpg (1.09 MiB) Viewed 42622 times

- EM port to runner transfer blending.jpg (1.16 MiB) Viewed 42622 times

So I enlisted the help of a local machine shop to bore the 24v flange to 1.65” inner. This is the exact ID of the exhaust runner material. It will be much easier to make the shape transition in the alloy had vs the 304 flange.

- bored 24v ex flange.jpg (1.08 MiB) Viewed 42622 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Thu Jan 30, 2014 10:11 am

by my2000apb

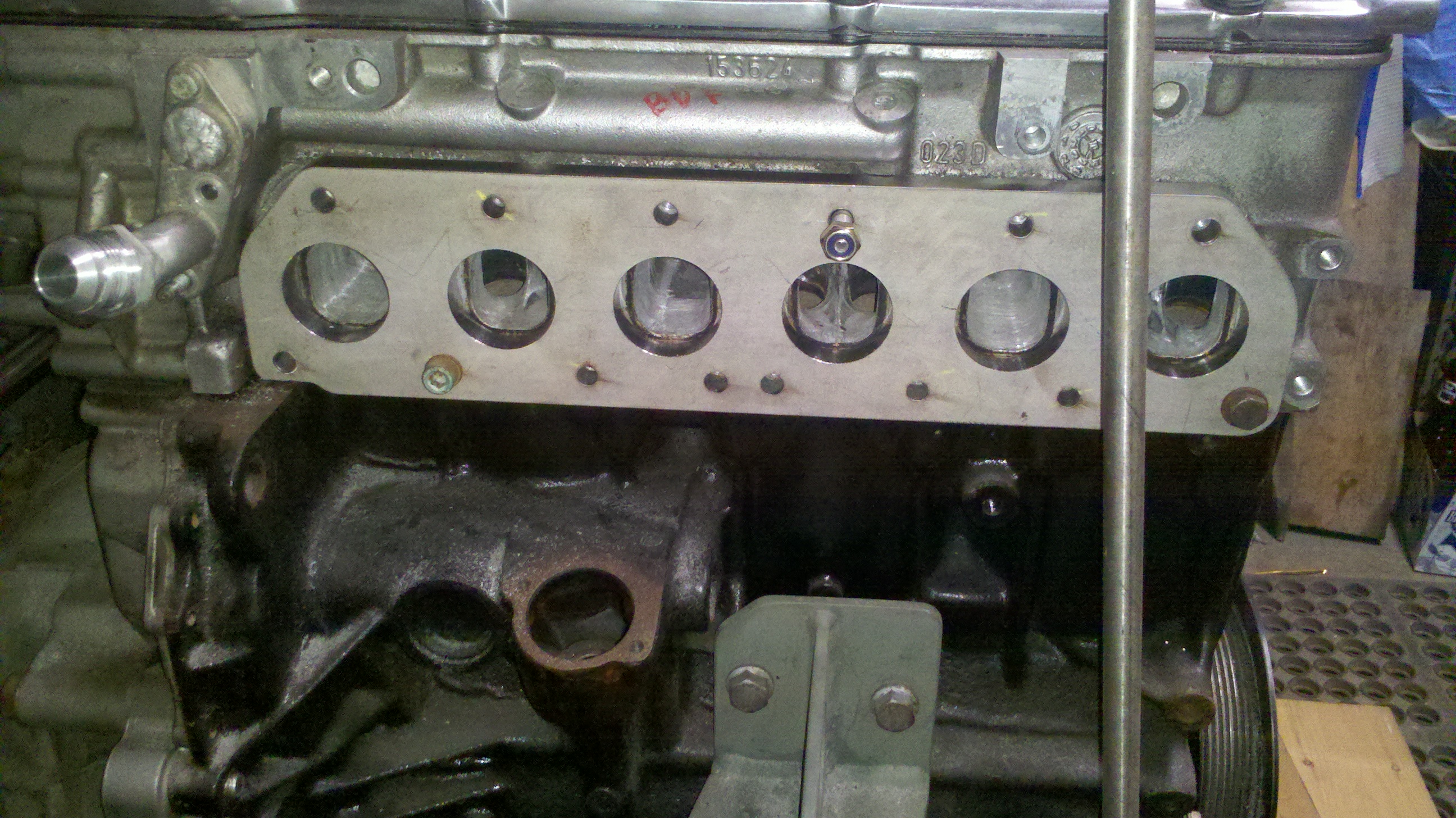

More! Here is the bored flange in place on the head

- exhaust manifold flange bored and inplace.jpg (1.4 MiB) Viewed 42639 times

Here you can see the shape differences marked on the head

- runner shape transfer markings.jpg (1.23 MiB) Viewed 42639 times

And a sexy vband weld pic

- WG vband outlet welded.jpg (2.47 MiB) Viewed 42639 times

And for the downpipe im running a BW S300 DP flange / vband. Here you can see the inside and outside line up, fits great!

- hx40 flange and s300 dp flange inside.jpg (1.18 MiB) Viewed 42639 times

- hx40 flange and s300 dp flange.jpg (835.89 KiB) Viewed 42639 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Thu Jan 30, 2014 10:13 am

by my2000apb

MORE!!!

I finally got a HUUUGE pair of snap ring pliers so I could take off my Holset compressor housing. I got it off and then cut off the Holset specific v-band connection. I will be adding a short outlet extension to the compressor cover to get the clamp away from the hot manifold runners. A Vanjen clamp will be welded to the end once location/angle is finalized.

I busted out the carbides and smoothed the compressor outlet as best possible. I will get it a bit more once the extension is welded on.

- compressor outlet transition smoothed to vanjen.jpg (1.54 MiB) Viewed 42639 times

- compressor outlet transition smoothed to vanjen detail.jpg (1.51 MiB) Viewed 42639 times

I also picked up a 15,500 MILE!!! R32 head, it is suuuper fresh and clean. Its still that nice, matte alu color, it hasn’t even started to golden up at all.

- mmmm fresh head.jpg (1.62 MiB) Viewed 42639 times

- mmmm fresh head2.jpg (1.77 MiB) Viewed 42639 times

And lastly I got my helper spring dividers back from my machinist buddy and they look sweet!!

- helper spring dividers.jpg (352.67 KiB) Viewed 42639 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Thu Jan 30, 2014 10:14 am

by my2000apb

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Thu Jan 30, 2014 10:16 am

by my2000apb

MORE!!!

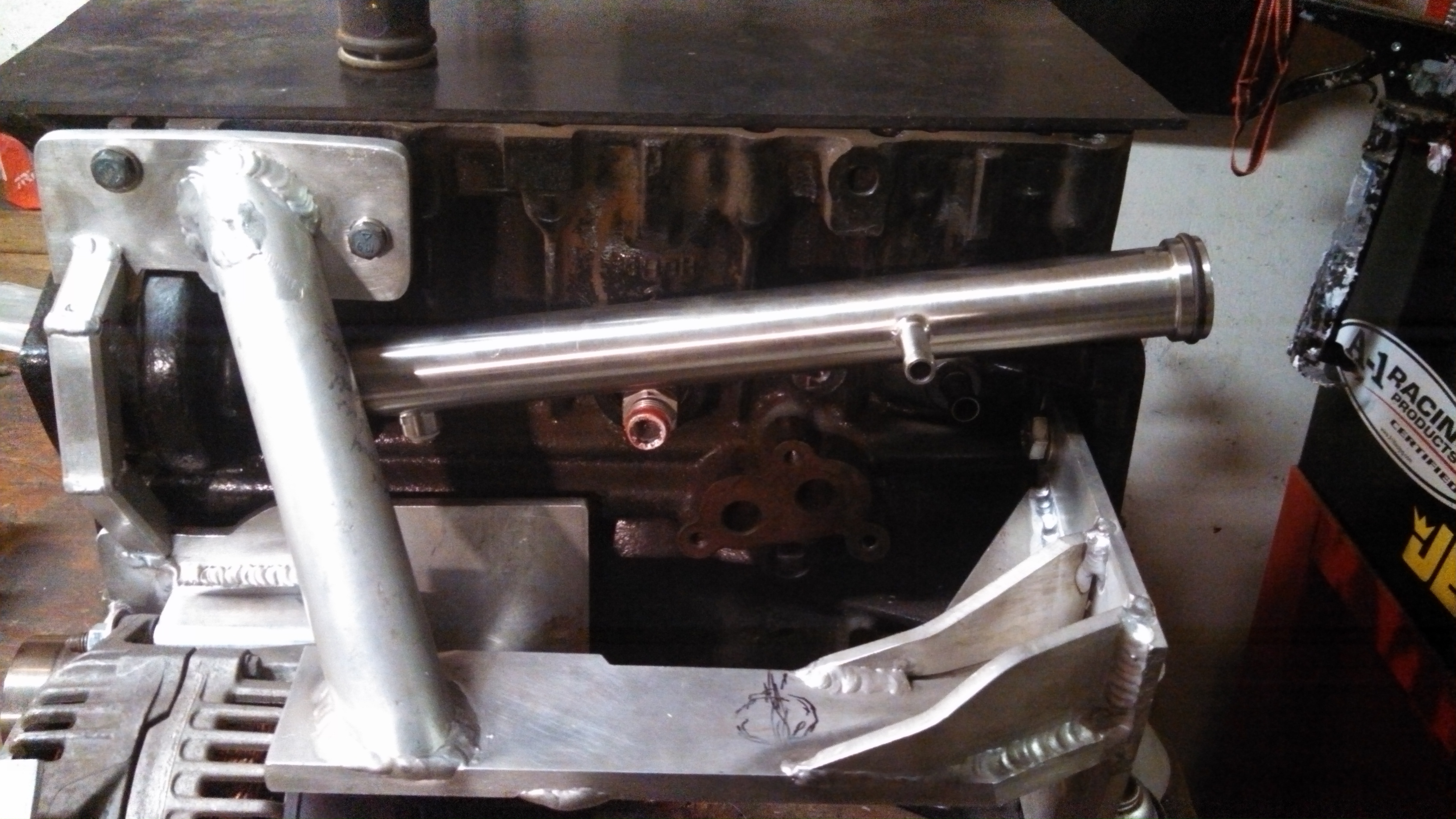

I also picked up a stainless vr6 crackpipe, cheeeap and brand new. I will be installing my remote thermostat housing connection in the middle of the pipe and make a smooth transition towards the water pump. I will also make a few “anti-rotation” tabs to help hold the crackpipe as the weight of the thermostat (not much but still) will be trying to make it rotate under its weight.

- coolant pipe and drv side eng mount arm.jpg (1.49 MiB) Viewed 42639 times

Then I will be able to finalize the 20AN inlet/outlet for the radiator!

I got some more parts back from my machinist buddy, a coolant / crackpipe receiver piece as well as an outlet block for the back of the head. I have a few 6061 weld elbows that I will utilize to make a very low clearance unit that easily clears the steering arms.

- coolant pipe reciever.jpg (267.03 KiB) Viewed 42639 times

the small hole in the head outlet unit will be manually opened up, I just didn't want to drill it all, ill be making a very smooth transition.

The smaller hole on the back of the crackpipe receiver is there to allow coolant to circulate while the thermostat is closed. As per the factory unit.

Pics!!

- vr6 head coolant outlet block.jpg (390.45 KiB) Viewed 42639 times

- vr6 head coolant outlet block2.jpg (290.32 KiB) Viewed 42639 times

- vr6 head coolant outlet block3.jpg (342.44 KiB) Viewed 42639 times

Re: 24vVR6T CQ Project: EATSGTR, chassis FAB

Posted: Sat Feb 01, 2014 12:30 am

by All_Euro

Another awesome update - great work.

Done any test runs with the meth injection on your intake mani? Just curious about the depth of the meth bungs... seems like the conical spray would hit the sides before it reaches into the runners. I plan to inject w/m into my runners too - nothing fancy though, just drilling holes and threading them.